Efficient Wood Pellet Maker Machine For Pellet Factory Setup

As a novice in building a wood pellet plant, it is vital to understand the equipment used in commercial wood pellet plants. The machines used to process wood fuel pellets affect the quality and output of wood pellets. Therefore, novices need to carefully consider how to select and buy wood pellet processing equipment when building a wood pellet production plant. What investors should especially pay special attention to is the selection of wood pellet pelletizer machines in wood pellet production. Next, in this post we will separately introduce which machines and equipment are needed in the wood pellet production line.

Buy Wood Pellet Maker Machinery

Wood Pellet Maker Machine: The Core Equipment of Wood Pellet Line

The core aspect of wood pellet production is manufacturing of wood pellets and this step is crucial. To make wood pellets efficiently, you need to have a quality wood pellet mill. A wood pellet machine is a key piece of equipment that converts pre-treated wood or other biomass feedstock into high-density, uniformly sized wood pellet fuel. Wood pellet making machine is the core equipment of the wood pellet production line. Therefore, investment of wood pelletizer equipment needs to be paid more attention to, especially for newbies.

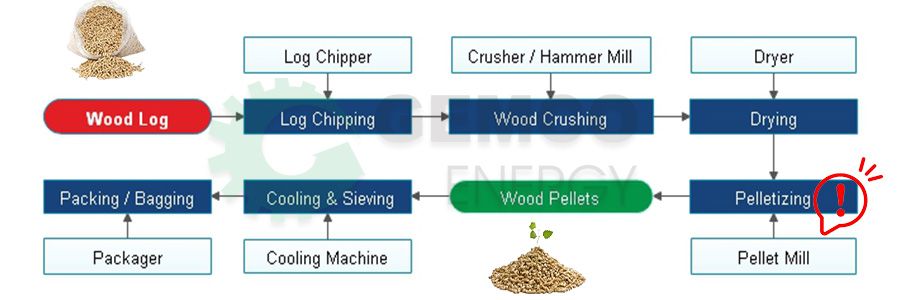

Biomass Wood Pellet Plant Process Flow Chart

Flat Die Pellet Mill vs. Ring Die Pellet Mill

In the market, there are two main types of wood pellet maker machine: Flat Die Pellet Mill and Ring Die Pellet Mill. Choosing the right wood pellet production machine for you usually depends on your budget and expected output. Let us understand the difference between these two types of pellet press machines.

Flat Die Wood Pellet Maker Machine & Ring Die Wood Pellet Maker Machine

- Flat Die Wood Pellet Machinery:

Flat Die Wood Pellet Mill is a common type of mini and small pellet maker machine for small or medium scale wood pellet production. It is also a homemade wood pellet maker. It can be divided into electric pellet mill, diesel pelletizer machine, PTO pellet machine and gasoline pellet maker according to different power. Flat die pellet processing machine is characterized by relatively simple structure and easier operation, suitable for beginners or users with limited budget. Flat die pellet maker machine is capable of producing high quality wood pellet fuels, but usually have a lower output with lower prices.

- Ring Die Wood Pellet Machinery:

Ring Die Wood Pellet Mill is a more advanced wood pellet model for large-scale production. It has a complex structure and a high degree of automation, allowing for large-scale production and high throughput. The advantages of the ring die pellet maker mill include high productivity and the ability to produce large quantities of high-quality wood fuel pellets, making it suitable for the production of commercial biomass pellet plant where large quantities of pellet fuel are required.

Gemco Wood Pellet Maker Machine Price

| Classification | Flat Die Pellet Mill | Ring Die Pellet Mill |

|---|---|---|

| Production Capacity | Small scale production pellet machine | Large scale production pellet machine |

| Production Yield | 60-1000kg/h | 1-12 TON/h |

| Energy Consumption | Generally low | Generally high |

| Wood Pellet Mill Cost | >$530 price relatively cheap | >$15,000 price relatively expensive |

| Applications | Family farms and small plants | Medium and large plants |

Whether you choose a flat die pelletizing mill or a ring die pelletizing machine, you need to consider your needs, budget and expected output. Our wood pellet processing machine sales team can provide you with expert advice to help you choose the best type of wood pellet making mill for your business. If you have any questions or need further information about biomass pellet maker machine, please feel FREE to contact us and we will be happy to serve you! (Link to Biomass Pellet Plant Process>>)

Auxiliary Equipment: Tools for Boosting Wood Pellet Production Efficiency

Auxiliary equipment plays an irreplaceable role in improving the efficiency of wood pellet production. Crushing, packing, drying, and cooling are indispensable links in the wood pelletizing system, which is of great significance in improving production efficiency and product quality.

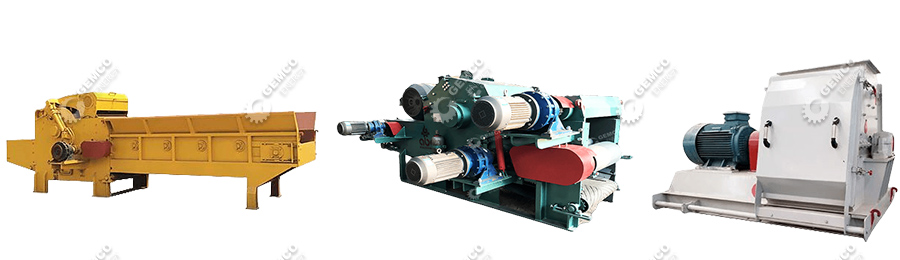

Wood Chipper and Wood Hammer: Crushing Raw Materials in Wood Pelleting Line

Crushing Machine & Wood Chipper & Hammer Mill

Reducing feedstock size is the first step in a wood pellet mill plant. Reducing the feedstock size through processes such as crushing and chipping prepares it for subsequent processing and production steps.

Different types of wood crushers have different advantages and uses. Chipper machine usually processes the feedstock into chips with thickness less than 3mm and length 10~30mm. Hammer equipment can crush the feedstock into different sizes of sawdust according to the specific needs of the wood pellet processing plant. Therefore, novices need to choose this production equipment according to the specific production needs when preparing a biomass pellet production plant.

If you have questions about wood crusher, chipper, and hammer machine or would like more information, ask us for a free consultation!

Pellet Dryer and Cooler Equipment: Optimizing Pellet Quality in Wood Pellet Making Line

After the pelletizing process is completed, the wood pellets still contain a certain amount of moisture. In order to produce high quality wood pellets, the pellets must be dried and cooled.

The Pellet Dryer reduces the moisture content of the pellets to a suitable level, usually between 8% -12%. During the drying process, the temperature and air velocity need to be controlled to prevent the pellets from over drying or overheating. Afterwards, the pellets are cooled in a Pellet Cooling Machine to stabilize the shape and quality of the pellets.

Pellet Packing Machine: The Final Link in Wood Pellet Production Process

The Packaging process is the last part of the wood pellet fuel production line. The Pellet Packing Machine is designed for packaging wood pellets, which can automatically complete the work of packaging, sealing and marking to improve production efficiency and reduce production costs. Good packaging not only ensures that the wood pellet fuel is not damaged during storage and transportation, but also improves the product image and enhances customer trust.

Rotary Dryer & Pellet Cooler & Pellet Packing Machine

From Novice to Pro: Harnessing GEMCO's Wood Pellet Machine Equipment and Services

GEMCO is one of the top professional wood pellet mill manufacturers in China, and has helped companies in the UK, Australia, Portugal, Italy, Serbia, Morocco, Vietnam, Thailand, New Zealand, the Philippines, Bulgaria, Ghana, and many other countries to realize the profitability of their wood pellet plants for 30 years. Therefore, choosing us as a consulting service company will be a very wise choice.

If you want to know more about the products of wood pellet production projects, please feel free to contact us, GEMCO engineers will provide professional answers for you!