building a wood pellet factory: tips and tricks

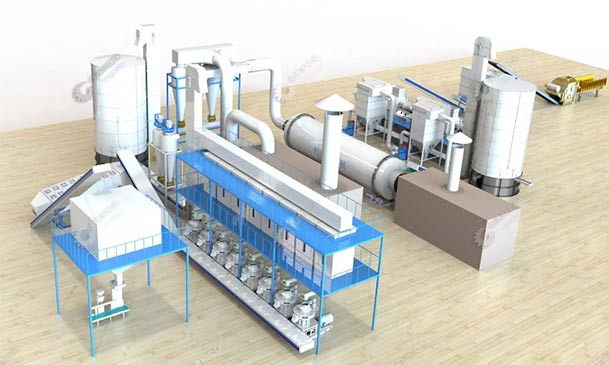

Welcome to the GEMCO-Energy, here we provide ultimate guide for setting up a complete wood pellet plant from scratch. In this column, you will get a step-by-step guide on how to set up a wood pellet plant, including wood pelletizing equipment, wood pellet production process, and cost analysis to set up a complete wood pellet mill. Whether you are a beginner or an experienced investor, this guide will help you understand the wood pellet industry and establish your own wood pellet production business.

- Flat Die Pellet Mill Design Strategies for Successful Production in Plant

- DIY wood pellets with homemade pellet mill

- Raw Materials Sourcing for Wood Pelletizing Plant -Lignocellulose

- Wood Pellet Plant Investment Analysis: Estimating Setup Costs

- Effective Dust Control Measures for a Complete Wood Pellet Plant

- Thorough Equipment Selection Guide for Wood Pellet Plant Setup

- Strategic Wood Pellet Plant Design: Enhancing Workflow and Output Quality

- A to Z Guide for Sawdust Pellet Production Line: Maximizing Productivity and ROI

- From Plan to Production: Key Considerations to Setup Wood Pellet Mill Plant

- How to Buy a Cost-effective Pelletizer Machine Online?

- Factory Price Small Ring Die Pellet Machine

Building a Successful Wood Pellet Plant: Our Expert Approach

Opportunities to Setup Wood Pellet Plant

The global market for wood pellets has increased significantly over the past several years, and this trend is anticipated to continue due to the ing awareness of environmental benefits of wood pellets and their efficacy as a renewable energy source. Wood pellets are now universally recognized renewable energy source for its low cost, great efficiency, and little environmental effect and are widely used in power plants, residential heating, and more. In addition, starting a business in wood pellet manufacturing can get significant fiancial returns, ith a return on investment of up to 20% and a payback period of around 2-4 years, which attracts more and more investors in this sector.

- Increasing fossil fuel prices;

- Policy supports and measures by national goverments;

- Raw material availability and low cost;

- Sustainability standards, certified production and traceable chain management;

- Technical requirements for industrial wood pellet fuels;

Raw materials for pelletizing determine wood pellet production process and the setup of wood pellet plant, to a great extend.

If the raw material is sufficiently dry and the particle size is sufficiently small, then wood pelletizing process is relatively simple: pelletizing and cooling, just like to make wood pellets from sawdust.

If the raw material is dry but coarse and larger in size, it must be crushed before pelletizing, like making pellets from wood shavings.

If wet sawdust is used, the vast majority of sawdust coming from sawmills is wet, then it must be dried.

In order to achieve the required particle size, the shredding process is crucial in industrial or deep forest wood chip use. In addition, most wood pellet plants have to adjust the moisture content of the raw material with hot water or steam prior to pelletizing in the pelletizing plant. In any case, the appropriate raw materials, intermediate transition periods and fuel storage facilities adapted to the raw material pellet fuel supply structure have to be just right.

Wood Pellet Plant Setup Guide with Business Plan Design

GEMCO-Energy, since establishment in 1997, is dedicated to providing complete wood pelletizing solutions for customers around the world. With over 20 years of experience in the biomass energy industry, we specialize in designing, manufacturing, and installing complete wood pellet production lines. Our wood pellet plant setup services include project consultation, plant design, equipment manufacturing, installation, commissioning, and after-sales service. Contact us today for a free consultation and professional guidance on setting up your own wood pellet plant.