From Plan to Production: Key Considerations to Setup Wood Pellet Mill Plant

Wood pellets are a form of biomass, an environmentally friendly source of fuel that is quickly gaining popularity around this increasingly eco-conscious world. Production of this energy source takes place in wood pelletizer mills. If you are interested in joining the industry, you will need to know how to set up a wood pellet manufacturing plant of your own.In order to begin, you must know and understand the different steps that are taken in a wood pelletizer mill for production. This will allow you to be aware of the kinds of materials, machines, and equipment that you need. Here are the systems you will need in a wood pellet manufacturing plant.

Raw Material System

This part of the wood pelletizer mill focuses on directly handling and managing the raw materials used to form wood pellets. There are a few steps taken in this system.- Crushing. A crushing system is the vital first step in pellet production. Using timber, chips, or another similar source of wood, a machine will crush raw materials into smaller chunks. This is done via a hammer mill and wood chipper, and you have the option of using dust collectors to contain debris.

- Sieving. This step is optional in some pelletizer mills, but is important to avoid damage to your machinery. It involves getting rid of debris like stones from the crushed raw material.

- Drying. The water content of wood requires that the crushed materials are thoroughly dried. Excess water can result in lower quality pellets. For small scale productions, an air flow dryer will suffice, but larger productions will require a drum dryer.

Pellet Manufacturing System

Now that you have your chunks of wood, you will have to convert them into actual biomass pellets that can be used for fuel and purchased by customers and clients. This process is simple and involves a couple of steps.- Pelletization mill. This is where you will reduce the previously crushed raw materials into finished pellets. For smaller productions, a single flat die pelletizer mill will work fine, but you will need multiple for larger productions. Alternatively, invest in a ring die pelletizer mill for higher production output. (how to operate wood pellet mill correctly?)

- Cooling. Completed pellets have a high temperature and have to be cooled before they can be packed and moved to the next process. A counter flow cooler is a good option for this process as it can sieve broken, powdered, or damaged pellets away from the good ones for better quality control.

- Packing. Once you are done cooling and sieving, it is time to pack the pellets for storage, shipment, and sales. Any standard factory bagging procedures work fine for this purpose, and you can choose the size of the bags as appropriate for your business.

While there are many components to consider in setting up a wood pellet manufacturing plant, this guide will help to get you started so you can begin searching for the equipment you need. Wood pellet and biomass pellet production is a great sign that the world is moving towards more environmentally friendly fuel.

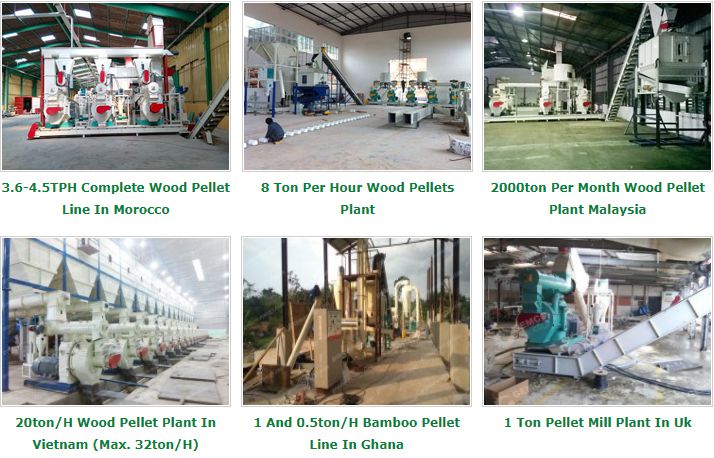

Pellet Manufacturing Plant Successful Case

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!