Animal Feed Processing Techniques and Equipment

Animal feed processing plays a vital role in the farming industry. This complex and sophisticated system encompasses several steps and technologies. From the selection of raw materials to the processing of the final product, each link in the feed processing flow carries important functions and responsibilities. This article will systematically introduce the basic process of animal pellet feed processing, delve into the importance of each step and its interrelationship, aiming to help readers fully understand this complex and sophisticated manufacturing process. It is expected that this column will provide valuable knowledge and skills for investors in the animal feed industry or farmers who want to make their own feed.

- Feed Storage Process: Strategies for Animal Food Processing Plants

- Feed Packing Process: Animal Feed Packaging Machine in Manufacturing Companies

- Pellet Crumbling Process: Application of Crumbler Machine in Animal Feed Pellet Mills

- Feed Expanding: Upgrading Animal Feed Manufacturing Process with Extruder Machines

- Feed Cooling Process: Importance of Animal Feed Pellet Cooler in the Production Line

- Crushing Process: Innovative Animal Feed Production Techniques

- Feed Material Conveying: Reducing Costs in Animal Feed Processing Plants

- Pelletizing Process: Advanced Animal Feed Pelleting Machines and Techniques

- Feed Mixing Process: Buying Animal Feed Mixer Machine for Your Plant

- Feed Batching Process: Vital Element in Animal Feed Business Plans

- Raw Material Cleaning: Crucial Tactics of Advanced Animal Feed Milling Plant

- Raw Material Reception: First Step to Animal Feed Plant Profitability

Key Steps in Animal Feed Processing: Manufacturing Process and Machine

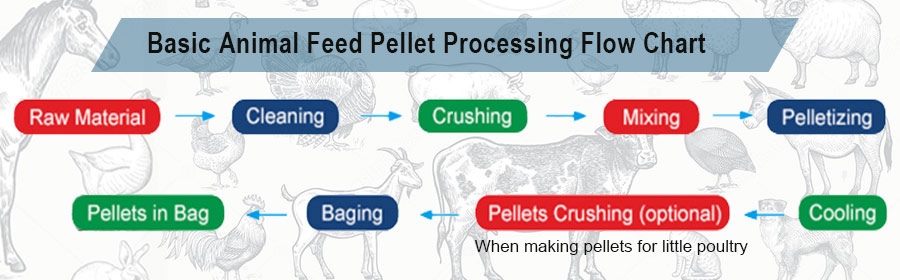

Today's animal feed market is dominated by pelleted feeds, which are popular among breeders. Because they are easy to store and transport, help with nutrient absorption, and reduce feed waste. Below is a common basic animal feed processing flow of pellet for your reference. However, you must be reminded that animal feed processing equipment price in feed pellet processing line varies depending on the requirements of the animal feed and the scale of production. If you have any needs, welcome to consult us about specific animal feed mill plant processes and prices for free!

Animal Feed Manufacturing Process Flow Chart

- Selection of Raw Materials

At the initial stage of animal feed processing, after detailed market research and quality assessment, animal feed mills should focus on selecting high quality raw materials. Grains, legumes, fats, vitamins, and minerals are the main ingredients in animal feed formulations. Animal feed manufacturing plants can work with reliable suppliers to ensure that the raw materials meet standards and have high quality nutritional value.

- Reception and Cleaning of Raw Materials

Upon arrival of raw materials, animal food processing plants implement a strict acceptance program. This includes inspections for appearance, odor, and purity. Next, a cleaning step is performed to remove foreign matter, impurities, and substandard ingredients to ensure purity and quality of animal feed pellets.

- Crushing of Raw Materials

The raw material enters the crushing equipment to be processed to obtain the desired particle size and fineness. This step is crucial for subsequent mixing. Specialized animal feed crusher machines are used in the animal feed pellet production line to pulverize the ingredients to the desired particle size, helping that the various ingredients of animal feed formulas can be evenly mixed to improve the overall quality of the feed.

- Batching (Blending)

At this stage, the ingredients are mixed according to the precise proportions of the animal feed recipe. Feed milling plants should strictly control the accuracy of the dosing process to ensure that the chemical composition of each batch is uniform and the mix is stable, so as to achieve the target performance of the animal feed pellet product design.

- Mixing of Ingredients

Under the precise pellet feed formula control, various ingredients are put into the animal feed mixing machine according to the proportion. The scientific mixing process of animal feed mixer machine ensures that the nutrients are fully mixed and homogenized, resulting in a high quality feed ingredient.

- Pelletizing Process

The mixed raw materials are molded through the animal feed pellet processing machine. This is the process of turning powdered materials into pellets and is the most central step in the entire animal feed production process. The size, shape and density of the pellets are controlled through the use of appropriate animal feed pelleting machine and equipment, utilizing high pressure and molds to ensure that the quality of the final product meets standards.

- Cooling and Drying

After pelleting, the product enters a cooling and drying system to remove residual moisture and stabilize the product. This process uses specialized animal feed pellet cooler machine and drying machine to ensure that the product not only meets quality standards, but also extends its shelf life.

- Pellet Crushing (optional)

After cooling and drying, depending on the feeding requirements of the specific animal, the product may need to be further processed to ensure that the product meets the specified pellet size and shape. Typically, some chicks and nestlings require crumbled feeds for ease of ingestion and improved digestibility. In addition, some livestock (cattle, pigs and sheep) and small mammals (rabbits and hamsters) often require pellet crushing.

- Packaging and Storage

Use animal feed bagging machines to package the products and store them in a suitable environment. The feed production line uses packaging materials that meet hygiene standards and strictly controls the packing process to ensure that the products are not contaminated or damaged during transportation and storage. Suitable packaging and storage conditions help maintain the freshness and quality of the product and extend its shelf life.

Dear investors, you need to be careful about investing in animal feed production plants. Different animal feeding needs require different feed processing technology and methods of feed mill plant and equipment parameters. To ensure the success of your animal feed processing plant investment, it is recommended to look for a professional animal feed engineering service company. If you are confused about buying machines for setting up your own animal feed plant, do not hesitate to contact us!

GEMCO: Trusted Expertise in Animal Feed Processing Solutions

GEMCO, one of the top animal feed machine manufacturers in China, has helped many investors successfully implement many feed pellet engineering projects in many countries around the world. Regardless of the size of the production, we offer complete feed mill plants and can customize a solution to fit your needs. We provide full technical support and service to ensure the efficient and stable operation of your production line.

Contact us now for a free consultation to get feed plant layout and design!