Crushing Process: Innovative Animal Feed Production Techniques

When talking about the vital aspects of the animal feed production process, crushing is undoubtedly one of them. The feed processing definition of milling is the process of using mechanical impact, grinding or shearing to refine the particles of raw materials. It has a direct impact on the cost, quality and yield of the feed. In particular, it is important to note that, in general, the energy required for common milling systems accounts for 1/3 of the total power supply of the feed plant, which means that the milling process and machine also affect the animal feed plant cost. Next, let's take a closer look at the processes and equipment used to crush raw materials, and the relationship between crushing and dosing of feed ingredients. I hope the knowledge I've shared will help you with your feed milling business plan.

Crushing and Dosing Methods in Animal Feed Mills

Why Is Grinding Feed Ingredients Essential in the Feed Production Process

- Improve feed digestibility and enhance feeding effect. By crushing, the contact area with the digestive liquid is enlarged.

- Easy to mix evenly and improve feed quality. The closer the size of the ingredients, the easier it is to mix them well.

- Satisfy customers' needs and improve sensory properties. Good sensory helps feed sales.

Influence Of Pellet Feed Diameter

| Particle Diameter/μm | Digestibility Rate of Dry Matter | Feed-to-Meat Ratio |

|---|---|---|

| <700 | 86.1 | 1.74 |

| 700~1000 | 84.9 | 1.82 |

| >1000 | 83.7 | 1.93 |

What is the Difference Between Pre-Grinding and Post-Grinding

In the animal feed production process, the feed crushing process is closely related to the animal dosage process. In the animal feed mill, the combination of the crushing and dosing process can be divided into two forms: first crushing and then dosing process (pre-grinding) and first dosing and then crushing process (post-grinding). Next, we will explore the process, characteristics and application of these two feed processing techniques one by one.

Powdered Feedstuffs of Animal Feed Making Plant

Grinding Prior to Ingredient Mixing Technique in Animal Feed Processing Plant

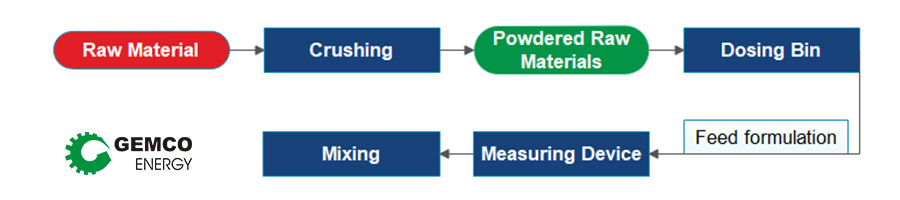

The process of crushing before batching (pre-grinding) is to crush the animal feed ingredients one by one to make them into a single species of powdery raw material for animal production, and then convey them to the batching bin. Then, according to the animal feed formulation, powdery raw material will be measured by the measuring device which is under the batching bin and lastly enter the animal feed mixer machine for mixing.

Animal Feed Crushing Before Dosing Processing Flow Chart

- Advantages Of Using the First Grinding and Then Batching Technology

This crushing process in the animal feed production process handles granular feeds one by one, using uniform parameters, ensuring stable operation, using the animal feed crusher machine efficiently, and reducing wear and tear on the animal feed processing equipment of the feed production line.

The grinding process does not directly interfere with other animal feed production processing steps. During maintenance of the milling machine, it does not interfere with other animal feed processing machines manufacturing animal feed pellets.

The degree of crushing can be controlled separately for different feed materials. This feed processing technology helps to regulate the sensory characteristics of the finished material and improve the final feed quality.

- Disadvantages Of Using the Milling Before Dosing Technology

The disadvantage of this process is the complexity of the process and large investment.

The batching silo is easy to arch, increasing the workload of batching silo management in animal feed production plants.

If the feed formula involves more raw materials for feed production, it is easy to be restricted by the batching silo when changing the feed formula.

The process is suitable for the need to crush the feed ingredients in the feed formula which is a small proportion, large-scale production, diverse products, high-quality products required of feed plants applications. Large and medium-sized animal feed manufacturers produce many varieties of feed, concentrates and premixes account for a large proportion of the product. Therefore, this process is very suitable for large and medium-sized animal feed plants.

Ingredient Mixing Preceding Grinding Technique in Animal Feed Production Plant

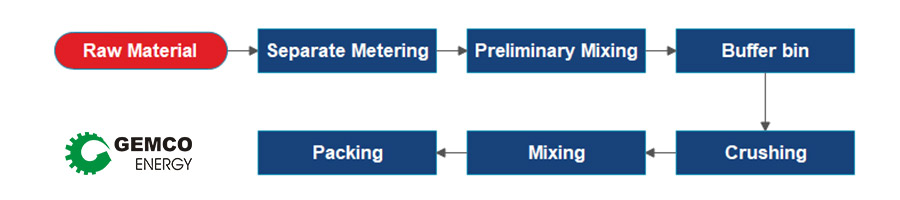

The mixed and then crushed process is a variety of ingredients in accordance with the requirements of the proportion of animal feed formula were measured, mixed and then crushed and finally need to be fully mixed again.

Ingredients Before Crushing Process in Animal Feed Manufacturing Line

- Benefits of Ingredient Mixing Before Grinding Process

The batching, crushing, mixing and other processes of this feed processing flow are in good continuity, and easy to automate control.

Because of the first preliminary mixing and crushing, the need to crush the feed material to occupy the number of batching silos is less, reducing the investment in equipment and equipment covers an area.

Reduces the probability of arching in the batching silo and facilitates the management of the batching silo.

- Drawbacks of Grinding After Ingredient Mixing Process

High installed capacity and high energy consumption. Mixing first and then powder is 20% higher than powder first and then the mixing process in terms of installed capacity and energy consumption is more than 5% higher.

Because the crushing process is after the batching process. During the maintenance and repair of the animal feed grinding machine, it will directly affect the other processes.

Because of a variety of granular raw materials mixed crushing, particle size, soft and hard degrees of different, it is more difficult to control the raw material crusher machine and easy to wear and tear.

The process is suitable for feed production with many varieties of raw materials to be crushed and a small proportion of the formula. Generally, small and medium-sized enterprises have less capital to build factories, and the site area is limited by the process that can use this process. In addition, this process is also suitable for aqua feed mills.

Crushing process in the feed production process is different, crushing efficiency, energy consumption per unit of output, crushing quality, degree of difficulty are different. Therefore the choice of crushing process is very important. If you have any questions about the crushing process and equipment, welcome to contact us for free answers!

Strategic Considerations for Buying Animal Feed Crusher Machine

Animal Feed crusher machine is the main factor that determines the quality of crushing. Therefore, animal feed mills should be careful in choosing animal feed machine manufacturers when purchasing an animal feed crushing machine. However, how to choose the best crushing machine? Here are some considerations when you buy an animal feed crushing machine for the animal feed production line.

Animal Feed Crushing Machinery for Sale in Commercial Feed Factory

- Flexible Adjustment of Crushing Particle Size: according to the requirements of different animal feed products, can accurately adjust and control the size of the crushed particles.

- Ensure the Uniformity of the Finished Particles: the crushed particles need to maintain consistency. The crushed material does not produce high heat. Ensure the uniformity and stability of feed formulation.

- Continuous Operation and Convenient Discharging: Continuous and stable feeding and discharge to ensure the continuity and high efficiency of the animal feed production process.

- Low Energy Consumption and High Efficiency: power consumption and energy consumption per unit of product should be low, but can maintain high efficiency working conditions to save energy costs.

- Wear-resistant and Easy-to-replace Parts: the main working parts need to have good wear resistance and be easy to replace and maintain to ensure the long-term stable operation of the equipment. At the same time, it is necessary to ensure a high degree of standardization of the crusher machine, to facilitate the purchase of parts.

- Reduce the Environmental Impact: minimize the dust and noise generated during the work, in line with environmental standards.

In addition, feed producers should also comprehensively consider the animal feed mill production scale, the amount of investment, the crushing process, product quality requirements and the characteristics of various types of crushers, to find the most suitable for the needs of the configuration program. If you want to know more about the crushing process or different models of crusher prices. If you want to get a customized animal feed production business plan pdf based on your specific situation, please don't hesitate to contact us directly. We will help you for free. (Read more about Animal Feed Process Flow Design>>)