8~10TPH Turnkey Poultry Chicken Feed Mill Plant Supplier

Based on the purpose and species of the bird, there are different forms of poultry feed for sales in the market. They may vary from each other on the basis of their nutrients type, concentration, and appearance, etc. Generally, poultry feed is classified into three types:

Poultry Feed for Sale

- Pellet Poultry Feed

This feed is prepared through the mechanical pressing of the mash feed. It is easier to manage and preferred for adult birds/chickens.

- Crumble Poultry Feed

It is similar to pellet feed but is less compact than the pellets. This kind of feed is preferred for the broilers.

- Mash Poultry Feed

The ingredients in mash poultry feed are in their ground and loose form. This well-balanced diet is usually fed to laying hens, turkey, and other local birds.

Why You Should Set Up a Large Commercial Poultry Feed Plant?

The world population is increasing gradually. Due to this reason, the demand for animal food is increasing continuously. Eggs and white meat are a great source of protein due to which people use them in many dishes. Feeding the poultry birds the right food that is full of essential nutrients is important so that the birds produce a healthy amount of meat and eggs throughout the year. (Read more: Poultry Feed Business in Nigeria >>)

Poultry feed is prepared carefully by keeping in mind the nutrient requirements of the bird. That is why poultry farmers rely on poultry feed a lot. Over the past few years, poultry feed production has increased by many million tons. It reached 1.103 billion metric tons in the year 2018. Its production is expected to increase more in the near future due to the high demand for valuable poultry feed. The high demand for poultry feed is increasing years by years, establishing a commercial poultry feed plant is a great opportunity to earn revenue and make your name in a growing business.

The poultry feed manufacturing plant cost varies from the capacity, equipment selected, final feed products and other factors. For detailed project cost and equipment list, please contact us directly to get the customzied plan!

Turnkey Poultry Feed Mill Plant Project Supplier

GEMCO has been specialized in supplying animal feed plant machinery for at least two decades. We mainly provides humanized design according to the investment cost and actual needs of customers. In the past years, we have built small or large scale feed mill plant project in many countries, like Philippines, Chile, Uzbekstan, Nigeria, Tanzania, Uganda, Fiji, Russia, Kenya, etc.

Latest Commercial Poultry Feed Plant Project Display

| Capacity | Poultry Feed | Project Design |

|---|---|---|

| 8~10 tons per hour | Chicken Feed Pellets | 5 layers |

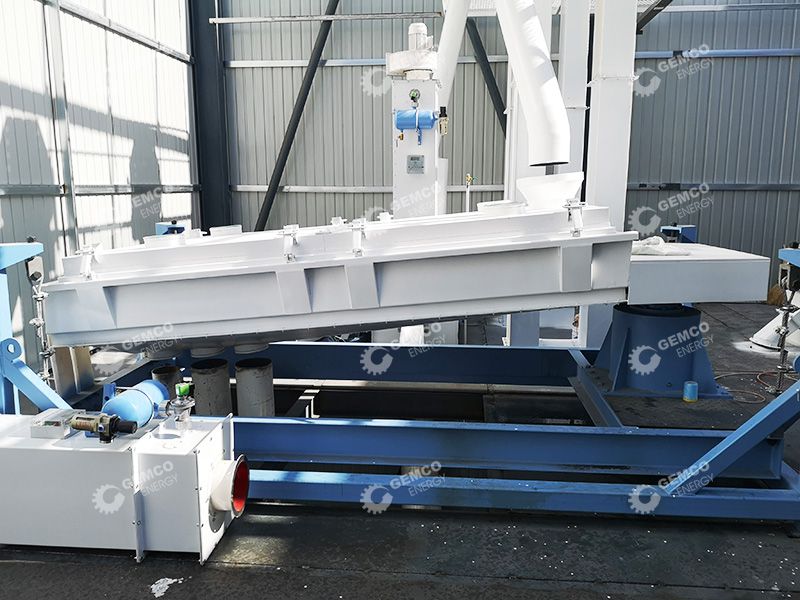

This is a new turnkey chicken feed pellet mill project undertook by GEMCO ENERGY. Check the main machinery of this poultry feed production line. If you are also planning to set up a commercial feed mill plant to produce high quality poultry feed, massage us your specific requirements to get the latest quotation!

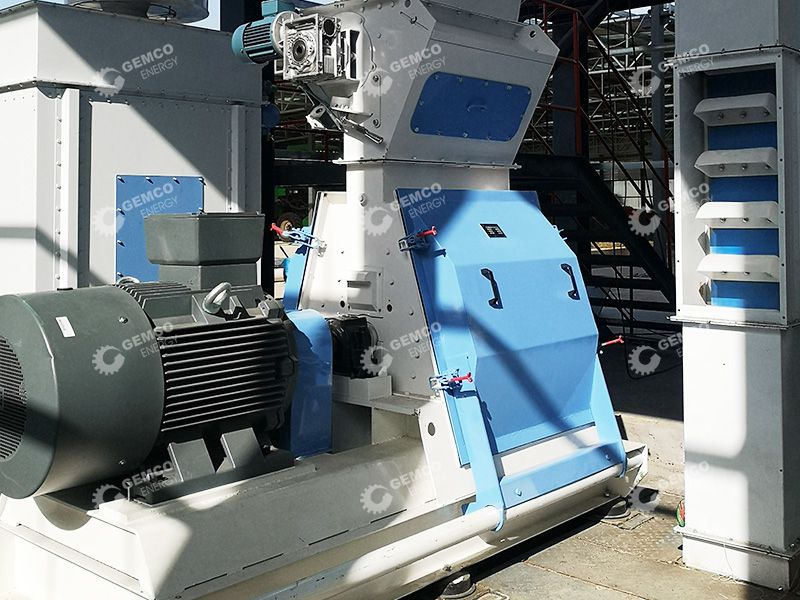

- First Layer: Crushing Machine, Mixing Machine, Cooling Equipment

- Second Layer: Feed Pellet Mill, Electric Cabinet, Weighting Scale

- Third Layer: 15 Feed Bins

- Fourth Layer: Rotatory Feeder

- Fifth Layer: Raw Material Cleaning Screen, Pulse Dust Collector, De-ironing Separator

Large Commercial Poultry Feed Plant Project Setup by GEMCO Energy

Setup commercial poultry feed plant | turnkey project – factory price feed processing machines for poultry feed manufacturing: buy high quality poultry feed processing machine from animal feed mill plant manufacturer or supplier at factory price, get FREE technical instruction of poultry feed production process and business plan to set up commercial poultry feed plant project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

Poultry Feed Pellet Manufacturing Process

Poultry feed pellet production requires a series of process and equipment. Some of poultry feed processing machines may not be equipped in small scale feed mill in order to save the investment cost. But, large scale animal feed manufacturing plant would equip all the neccessary machinery to improve the production efficiency and lower the production cost. (Read more: Feed Pellet Mill Machine Price >>)

- Purchase the Suitable Raw Material

Choose the raw material based on the purpose of poultry feed. The most common raw material includes rice husk, soybean meal, corn, rice, cottonseed cake, etc.

- Remove Impurities (Sieving)

Now remove the impurities such as dust, rock, etc. from the raw material. It is essential to enhance pellet quality.

- Grind the Raw Material (Grinding)

The cleaned raw material is then fed into a hammer mill which crushes it into fine-sized particles.

- Mix Ingredients Thoroughly (Mixing)

Additional ingredients are added to increase the nutritional value of pellets. They are mixed thoroughly to make sure all pellets have the same contents.

- Make Pellets (Pelletizing)

The processed raw material is fed into a feed pellet making machine. Inside the machine, rollers put pressure on the material due to which they get compressed and come out of the holes present in the dies in the shape of cylindrical pellets. In large commercial poultry feed plant, the ring die feed pellet machine is widely used.

- Reduce Pellet Temperature (Cooling)

Pressure applied in the above step increases the temperature of pellets which is reduced with the help of cool air. Pellets are also sieved to separate fine pellets from the broken pellets.

- Store Poultry Feed Pellets (Packaging)

To protect pellets from environmental factors, they are stored in durable bags.

A complete animal feed pellet processing plant setup can be easy if you can find a reliable and trustable supplier. At the same time, you can save the cost, energy and time. Anyway, if you are going to enter the industry of animal feed by establish your own poultry feed plant, you should take a lot of factors into consideration to ensure the success!