2PTH Chicken Feed Production Line Set Up for UK Customer

Chicken Feed Development in UK

Recently, one of our customer from UK purchased one 2PTH chicken feed production line to produce the chicken feed for his laying hens and broilers. From this UK customer, we have know more details about the chicken feed development in UK. While with changeable demand of chicken for nutrition, the traditional feed type cannot meet the present development and requirement.

- The poultry owners has increasingly interest in "functional" supplementary feed, which is able to improves animal intestinal function, metabolism and immune system, thereby promoting animal health.

- Due to the high demand for protein in animals, protein supplementation tends to exceed the nutrient levels, so does the phosphorus. Optimization of the nitrogen and phosphorus in the complete formula feed becomes more important.

- Crude feed quality. Crude feed such as forage or corn silage currently accounts for the majority of ruminant feed, but its quality and feed value may vary widely.

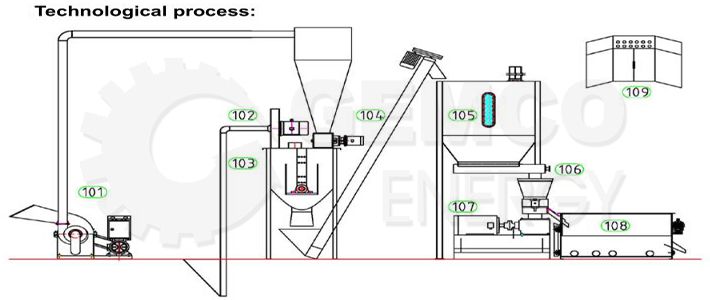

Customized Poultry Feed Production Line Process

Set Up Small Scale Poultry Feed Pellet Production Line

| 101 | Hammer Mill Crusher | 106 | Screw Feeder |

| 102 | Grain Grinding Machine | 107 | Feed Pellet Mill |

| 103 | Horizontal Mixing Machine | 108 | Pellet Cooling Machine |

| 104 | Screw Conveyor | 109 | Electric Control Cabinet |

| 105 | Temporary Storage Silo |

Generally, the poultry feed production line process consists of the following steps:

- At the beginning, the raw materials or the feed components, like soybean meal, corn, wheat, vegetables and other materials which are needed for animals is crushed into powders through the crushing machine.

- Then, in the mixing machine, the multiple crushed raw material powders are mixed completely for later pellet production process. In this process, the additive agents like vitamin, powder, bone and other necessary trace element can be added. Click here to know more about feed pellet making machine.

- Next, the mixed raw materials enter the poultry feed pellet making machine through the conveyor. Under the high temperature and high pressure inside the machine, the loose materials is pressed into high density solid pellet with uniform size and shape.

- After that, the finished pellet feed is cooled in the cooling machine for later packing and storing.

- Finally, through cooling and screening, the pellet feed can be directly packed into bags for storing.

Customized Chicken Feed Production Line for UK Customer

Why Choose Our Poultry Feed Making Machine?

We are one professional supplier and exporter of excellent range of Poultry Feed production line, exporting to over 50 countries and regions around the world. All of the offered machines meet the international standards of animal feed producing machinery, highly acknowledged for their power efficiency and characterized by a sturdy construction. All of our poultry feed making machinery finds vast application in the agricultural processing industry and are highly regarded for their optimal performance.Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!