Pellet Crumbling Process: Application of Crumbler Machine in Animal Feed Pellet Mills

The pellet crumbling process plays a key role in animal feed processing. By controlling the pellet size, animal feed pellet mills improve the taste, digestibility and nutritional balance of feed. Smaller pellets are easier to digest and absorb, promoting animal growth. The uniform mixing of nutrients in a crumble feed prevents nutrient imbalance and reduces dust, which helps to protect the respiratory system of the animals. In short, for animal feed mills, mastering the crumbling process, equipped with a pellet crushing machine is a wise choice to improve feed production efficiency, reduce animal feed mill costs, and gain market competitiveness.

Pellet Crumbler Machines Making Crumble Feed For Young Poultry

Significance of Pellet Crumbling: Reducing Costs of Animal Feed Mills and Farming Plants

The use of pellet crumblers in feed production makes significant economic sense. By increasing productivity, reducing energy consumption, accurately controlling pellet size and minimizing raw material waste, pellet crusher machines effectively reduce the costs of feed pellet mills and farms, providing a sustainable and economical animal production solution for the farming industry.

- Enhancing Animal Feed Utilization Efficiency by 15%~20%:

Excessively large pellets affect the digestibility of poultry and livestock animals and reduce feed utilization. Breaking feed pellets to the right size can increase feed utilization by 15% to 20%.

- Improving Animal Feed Pellet Nutrient Homogeneity by 25%:

Pellets are easier to mix with other feed ingredients after crushing, ensuring that animals get more balanced nutrition. The uniformity of mixing of various nutrients in the feed is improved by about 25% after pellet crushing.

- Boosting Livestock and Poultry Growth Rate by Approximately 10%~15%:

Properly sized pellets contribute to the healthy functioning of the animal's digestive system, reducing indigestion and other health problems, resulting in an increase in livestock growth rate of about 10~15%.

- Reducing Animal Feed Production Costs by 8%~12%:

Improving feed utilization and animal health reduces breeding costs during farming. Effective pellet crumbling can help farmers save up to 8 ~ 12 % on feed costs.

- Increasing Feed Pellet Production Line Speed by 30%:

The Pellet Crumbler can process large quantities of feed pellets quickly and accurately which increases animal feed pellet plant productivity. The use of the animal feed pellet crumbler machine has increased feed line processing speeds by up to 30%, reduced cycle times, increased yields, and reduced feed mill production costs.

If you would like to learn more about the benefits of pellet crumbling in commercial feed mills, you can click below to contact us directly.

From Pellets to Crumbles: Understanding the Crumbling Process and Crumbler Machinery in Feed Mills

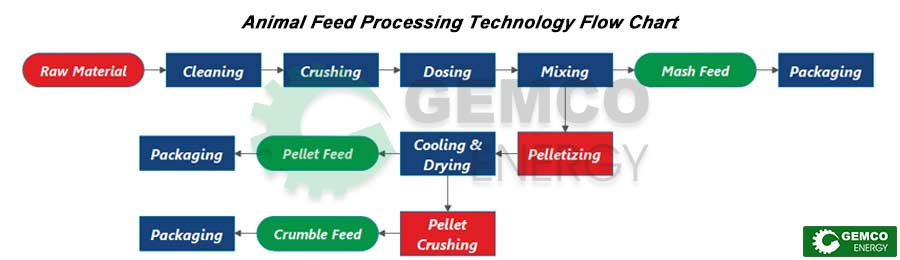

Pellet crumbling process is the production process of using pellet crumbler machines to crumble the large pellet feeds pressed by feed pelletizing machines into small pellet feeds. This process not only increases feed production by almost 2 times, but also significantly reduces the energy consumption of the animal production process, thus increasing the overall productivity of the animal feed production line. This method integrates two steps, optimizes the feed pellet production process, increases the efficiency of animal feed making, and at the same time reduces the waste of resources in the feed manufacturing process.

Mash & Pellet & Crumble Feed Manufacturing Process Flow Chart

Different forms of feed processing technology is different, the corresponding selection and configuration of feed processing equipment will also be different. If you want to know more detailed information, you can directly contact us to get free answers. We can help you with feed processing process and feed production machines. (Lick for more information about Processes ans Machines in Feed Production Line>>)

Pellet Crumbler Machine

Animals at different growth stages have specific needs for feed pellet size. However, when producing pellet feed, directly pressing small pellets using a die with a small hole size will lead to low output of the feed pellet machine, which consumes a lot of power of the feed pellet manufacturing line and increases the cost of the animal feed pellet mill. To solve this problem, the pellet crumbler comes into being. Pellet Crumbler Machine is a kind of professional feed processing equipment specializing in crushing large pellet feed (3~6mm) into small pellet feed (1.6~2.5mm).

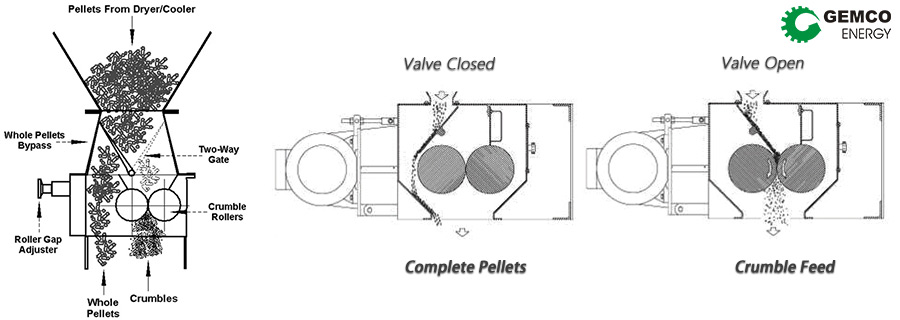

Demystifying the Working Principles of Pellet Crumblers

The pellet crusher used in feed mills is the roller crumbler. Roller crumbler machine utilizes a pair of rolls with unequal rotational speeds to rotate relative to each other. The feed pellets are fed from the cooling system through the valve of the crumbler directly into the middle of the two rollers. Through the differential speed movement of the saw-shaped teeth on the two rolls, the pellets are sheared and squeezed to make them crumble. The grinding size is obtained by adjusting the distance between the shafts of the two rollers.

If the pellet material does not need to be crushed, the lever can be operated to close the feed valve. At this point, the pellets pass through the bypass and the pellet crumbler motor does not work.

Feed Pellet Crumbler Machine Operating Principle

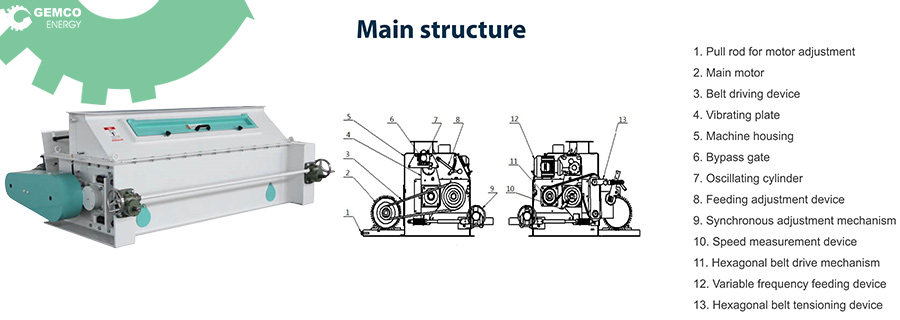

Structural Analysis of Pellet Crumbler Machine Design

Pellet crumbler machine mainly consists of the valve control device, the fast roller with a fixed position, the movable slow roller, the rolling distance adjusting mechanism, the frame and transmission device.

Best Price Pellet Crumbler for Sale

Among them, the rollers are the main working part of the pellet crumbling machine, and they are divided into fast and slow rollers. Fast roller and slow roller diameter, length, tooth shape are the same, just different speeds. Usually, the fast roller speed is 1.5 times or 1.25 times of slow roller speed. The distance of teeth on the surface of the roller is generally 2.5~3mm, suitable for crushing into 1.5~2.5mm crumbles. In order to make the roller run smoothly, increase the shear effect on the particles, and improve the crushing efficiency, the roller teeth of two rollers are often processing according to a certain slope (slope of 1:20). In the animal feed pellet processing mill, the general pellet crumbler is equipped with a pair of rollers. Large pellet crumbler machine mostly applies two pairs of rollers because of the limitation of roller length by processing equipment and manufacturing costs.

GEMCO: Your Expert in Animal Feed Processing Engineering

GEMCO's Feed Pellet Production Projects

The key importance of pellet crumblers in animal feed pellet production cannot be underestimated. To realize efficient feed pellet grinding, it becomes important for animal pellet feed mills to buy pellet crushing machines. If you are hesitating because of this, you can consider us. GEMCO, as an animal feed machine manufacturer for nearly 30 years, has been providing high-quality feed making machines and comprehensive services to customers in many countries and regions of the world, including Australia, Canada, Thailand, New Zealand, Chile, Uganda, Nigeria, etc.

GEMCO is committed to providing a full range of services to our customers. In addition to providing high-performance feed pellet maker machines, we also provide customized feed plant layout design and feed production equipment configuration suggestions for each customer. Contact us now! We will be pleased to help you achieve greater success in the animal feed processing industry.