Feed Material Conveying: Reducing Costs in Animal Feed Processing Plants

In this article, we will explore a special animal feed processing flow of the animal feed processing plant which carries an important responsibility without attracting attention - conveying process. This section is more than just the simple transportation of material, it is an integral part of the animal feed processing process. In the following, we will discuss the processing techniques and conveyor machine configuration of the feed conveying section, and then explore how advanced animal feed conveyor machines and conveying methods can be utilized to enhance the animal feed production process to increase yield, reduce energy consumption, and ensure a balanced distribution of feed.

Buying Conveying Systems for Your Own Animal Feed Production Plants

Categorization of Material Handling Conveyor Systems for Animal Feed Processing Plants

In the animal feed making process, each step is relatively independent. Raw materials from the beginning of the animal feed factory, you need to use a variety of conveyor equipment to complete material handling and storage. Raw materials are in the orderly flow between the various processes until the finished animal feed product is delivered to the animal feed making plant. Commonly, animal feed mills used conveying equipment are screw conveyors, belt conveyors, scraper conveyors, bucket elevators and so on.

| Horizontal Conveying Equipment | Screw Conveyor, Belt Conveyor, Scraper Conveyor |

|---|---|

| Vertical Conveying Equipment | Bucket Elevator |

Screw Conveyors (Spiral Conveyor): Efficient Material Handling Solutions

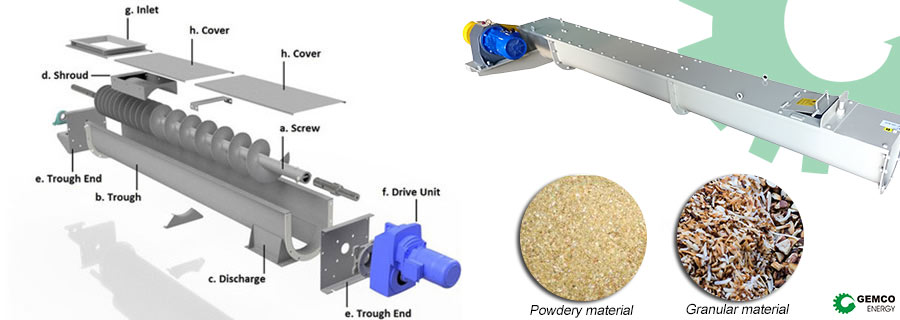

A screw conveyor consists of a screw (auger), a pipe and a drive unit. The screw is the key component of the whole conveyor machine, usually in the shape of a helix, located inside the pipe, which can be solid or hollow. The drive unit of the screw conveying equipment rotates the screw through the transmission system, thus pushing the material in the direction of the pipe.

Screw Conveyor in Animal Feed Processing Plant

A screw conveyor machine conveys material from one point to another along the pipe by pushing the material through the rotating screw. As the screw rotates, the material is propelled and moved in the direction of the pipe. This conveyor for material handling is suitable for conveying granular or powdery materials in animal feed processing plants. Screw conveying machine can be used for horizontal or inclined conveying of feed materials.

Exploring the Features of Screw Conveyors in Animal Feed Processing Plants

Screw conveying system, as an ordinary animal feed processing equipment, is suitable for short-distance conveying all kinds of powdery, granular, small lump and materials with good fluidity which are required for processing animal feed in feed mills. However, wet materials and fragile materials can not be conveyed by screw conveyors. Usually, for screw conveyor systems, the general horizontal conveying distance is not more than 15 m, the vertical conveying height is not more than 5 m, and the conveying capacity should not be too large, generally not more than 100 t / h.

Advantages of Screw Conveyor Machine

- The structure of screw conveying machine is simple and compact.

- Flexible and convenient installation, good adaptability.

- Good sealing, dust does not rise during material transportation.

- In the material conveying process, it has stirring, mixing and cooling effect on materials.

Disadvantages of Screw Conveyor Machine

- Due to the friction between the material and the blade and casing, the power consumption is large.

- Stirring and squeezing have crushing effect on fragile materials.

- Sensitive to overload reaction, easy to cause conveyor clogging when there are more organic impurities (straw, string).

Belt Conveyors: Streamlined Feed Conveying Systems

Belt conveyor machines are mainly composed of a conveyor belt (conveyor band), a drive unit and a support structure. Conveyor belts are usually made of rubber or polymer materials and can have different thicknesses and strengths depending on the needs of the feed mill.

Best Belt Conveyor for Sale in Animal Manufacturing Lines

A belt conveyor transports material from one location to another using a conveyor belt. A drive unit operates the conveyor belt and the material is placed on the belt and transported as the belt moves. This type of conveying equipment is suitable for all types of materials, including granules, powders and lumps.

Understanding the Key Attributes of Belt Conveyors in Animal Feed Plants

Belt conveyor, also called belt conveyor or tape conveyor, is an indispensable and economical conveying equipment to form a rhythmic flow line. The feed production line can use it for single conveyor or multi-set collaboration.

Benefits of Belt Conveyor Machine

- The feed material handling process does not damage the material and the material residue is small.

- Large conveying capacity and long conveying distance.

- Simple structure and convenient operation.

- Easy maintenance and management.

- Small friction resistance of each main part.

- Small noise at work, low power consumption.

Drawback of Belt Conveyor Machine

- Belt conveyor relies on friction to transmit force. Conveyor belts are easy to wear, and the cost of the conveyor belt is high;

- The conveyor equipment covers a large area.

- In the middle of unloading must add a unloading car.

- Difficult to seal, easy to raise dust when conveying powder in animal feed manufacturing plant.

Scraper Conveyors: Reliable Bulk Material Transport Systems

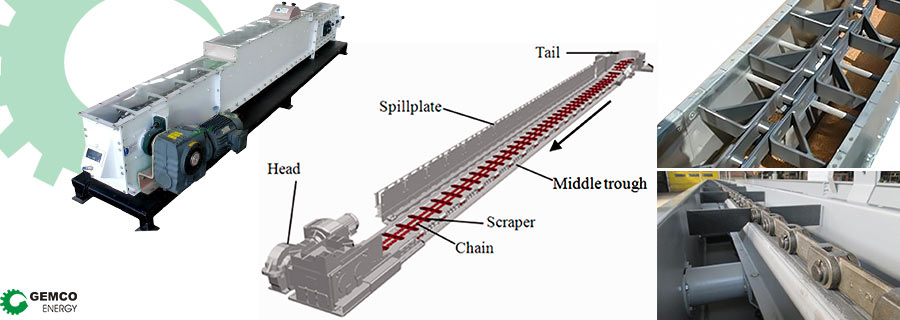

Scraper conveyor machine consists of a chain, scraper, driving device and rollers and other components. The scraper device is fixed on the chain and can be made of steel plates or other wear-resistant materials.

Raw Material Movemen by Scraper Conveyor

The scraper conveying machine utilizes a chain to drive the scraper to move along a fixed track, scraping the material from one place to another. The scraper is usually located at the bottom of the conveyor and pushes the material in the direction of the conveyance.

Unveiling the Characteristics of Scraper Conveyors in Animal Feed Processing Lines

Scraper conveyors are generally available in horizontal, inclined, and horizontal inclined types. The horizontal type is usually used for animal feed mill processing. The general Scraper conveyor conveying distance is not more than 50 ~ 60 m and the conveying capacity is not more than 150 ~ 200t / h.

Strength of Scraper Conveyor Machine

- Scraper conveyor has a simple structure. Manufacturing, installation, and use of maintenance are more convenient.

- Process setup is more flexible. Can be fed at any point in the conveying process.

- Good sealing, trough closed. Material conveying system can prevent the dust from rising and less material loss.

- Do not need many rolling bearings and expensive rubber belts.

Weakness of Scraper Conveyor Machine

- In the material transportation process, pellet materials are easily crushed.

- Compacting the powder material into lumps, causing floating chains.

- Higher friction between materials and scrapers and troughs, and easy wear and tear of conveyor machine parts.

- When no-load and underload, the traction parts sag, worsening the wear.

- Scraper conveyor working efficiency is lower than belt conveyor and bucket elevator.

The introduction of horizontal conveyor equipment has come to an end here. Feed producers need to pay attention to the different material handling systems having their characteristics, so it should be based on the nature of the material, conveying distance, production scale and other needs to choose the most appropriate equipment for material handling. Correct selection and use of animal feed conveying equipment, to ensure that animal feed production is continuous and orderly, improve labor productivity and automation level of production, and reduce the labor intensity of workers is of great significance.

If you are still confused about choosing a material conveying system or have questions about buying material conveyor equipment, we welcome you to contact us directly. We will provide you with professional answers and provide you with high-quality animal feed raw material conveying equipment services.

Bucket Elevators: Efficient Material Lifting Methods

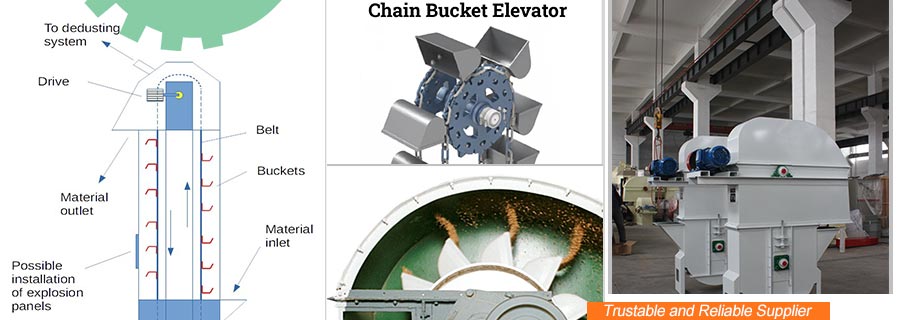

Bucket elevator is mainly composed of a bucket (barrel), zipper or chain, driving device and discharge device. The bucket is usually made of metal or plastic and attached to a chain or zipper.

Bucket Elevator: Material Vertical Lifting Transportation in Animal Feed Mills

The bucket elevator runs the bucket along the inside wall of the equipment using the chain or zipper. When the drive unit is activated, the bucket is lifted to the top of the equipment. The material inside the bucket is subjected to its own gravity and centrifugal force to dump the material outward. When gravity is greater than centrifugal force, the material slides along the inner wall of the hopper and is discharged, called gravity discharge. When the centrifugal force is greater than gravity, the material along the outer wall of the hopper sliding is thrown out, known as centrifugal discharge. When gravity is equal to centrifugal force, known as mixed discharge. Usually, the materials transported in the animal feed pellet plant are granules and powders, which are generally discharged by centrifugal and mixed discharging methods.

Discovering the Traits of Screw Conveyors in Animal Feed Conveying Systems

A sentence for animal feed manufacturers to summarize the use of the bucket elevator is that animal feed mills mainly use the fixed tape type elevator and generally use the type of reverse feed, deep bucket, and mixed discharge.

- Less Ineffective Power. Because the bucket elevator drive power is small, the use of inflow feeding, induced discharge, and large-capacity hopper intensive arrangement. There is almost no return and digging phenomenon when the material is lifting.

- Wide Lifting Range. This type of elevator has fewer requirements on the types and characteristics of materials. Not only can lift the general powdery, small granular materials, but also can lift the more abrasive materials.

- Good Sealing, Less Environmental Pollution.

- Good Operation Reliability. Advanced material conveyor design principles and processing methods to ensure the reliability of the machine, the elevator runs smoothly, so it can reach a higher lifting height.

GEMCO: Your Reliable Partner for Animal Feed Line Supplies

Conveyor sections play a vital role in animal feed processing lines. They are like blood veins connecting the decentralized processes and delivering the raw materials to the various processing stages in an orderly manner. High high-quality conveying system can effectively improve the production efficiency of the animal feed production mill, and ensure the coordinated operation of the animal feed production line, which directly affects the profitability of the animal feed processing mill. Choosing the right conveying equipment is not only a matter of individual performance, but also a matter of considering the animal feed plant layout and operational requirements. (Read more about Other Animal Feed Mill Processes>>)

Choose GEMCO as a partner in the construction of your animal feed mills. GEMCO, as a professional conveyor manufacturer, can understand your needs, design the optimal conveying system for your animal feed factory, select the most suitable conveying machine and provide the best service. Contact us now and let's work together on a successful animal feed business plan.