Feed Expanding: Upgrading Animal Feed Manufacturing Process with Extruder Machines

Expanded feed production processes and machines create more substantial economic benefits for farmers and are a key and indispensable part of modern feed plants. This article will delve into the principles and advantages of the expanded process, reveal its potential in the feed processing industry, and provide advice on the selection of feed expanding machines for investors ready to start an expanded feed business plan.

Buying Feed Extrusion Machine for Animal Feed Manufacturing Process

Advantages of Animal Expanded Feed Pellets: Advanced Feeding Solutions

Expanded feed pellets are a kind of puffed and porous pellet feed made by feeding powdered and pelletized feedstuffs into the extruder machine, after a continuous process of mixing, tempering, warming, pressurizing, extruding out the die holes, plummeting the pressure, as well as cutting into pellet segments, drying and so on.

Expanded pellet feed has the general characteristics of ordinary pellet feed, that is, good palatability, easy to store and transport, to avoid feed grading and feeding losses, etc., but also has the following advantages.

- Improve the digestive absorption rate of animals by at least 15%~20%. (Fish puffed feed can improve digestibility by 10%~35%)

- Improving the taste of feed and increasing the feed intake of animals by 25%.

- Reduces the number of microorganisms by more than 90% and has a good disinfecting effect.

- Feed moisture content is reduced by 15% on average, prolonging the shelf life of feeds.

- Suitable floating characteristics and anti-water stability can reduce water pollution.

- Differences Between Expanded Pellet Feed and Common Pellet Feed

| Feature | Expanded Pellets | Common Pellets |

|---|---|---|

| Extrusion Process | High-temperature and high-pressure extrusion | Not extrusion treatment |

| Particle Structure | More fluffy and loose | Relatively dense |

| Solubility | More soluble in water | Relatively poor solubility |

| Digestibility | More easily digested and absorbed | Relatively lower digestibility |

| Nutritional Value | Enhance the utilization of certain nutrients | Nutrients are relatively closer to the original state |

| Pellet Price | Relatively high price | Relatively high price |

If you have questions or are interested in expanded feed pellets, click below to consult us for free!

Understanding Techniques and Principles of Expanded Feed Processing

Through a deep understanding of the expanded feed processing process and the production principles, animal feed production mills can better gain a more comprehensive technical understanding, optimize production processes and improve feed quality.

A Deep Dive into Expanding Feed Processing Techniques

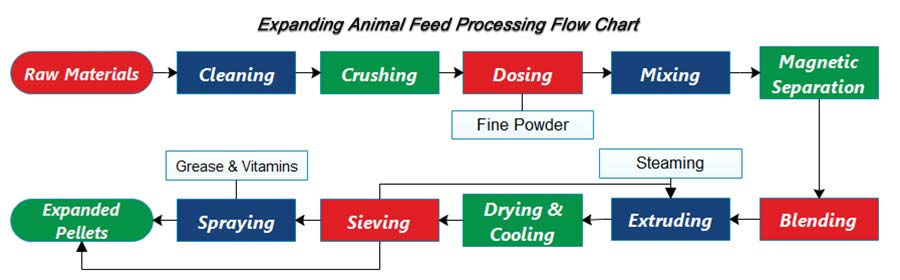

Animal Expanded Feed Processing Flow Chart

All kinds of raw materials are mixed and batching, and then enter the conditioner to be conditioned. At this time, the animal feed production line will spray saturated water vapor into the conditioner for temperature and humidity adjustment. At the same time, feed mill workers also add seasonings, colors, fats, oils, and liquids such as meat slurry to the conditioning machine to mix. The working parts of the conditioner make the temperature and humidity of the material uniform and consistent through stirring. For dry expanded feed, the moisture content of the wet base of the material after tempering is 20%~30% (usually between 25%~28%), and the temperature is suitable between 60~90℃. (Read more about other Aniaml Feed Manufacturing Process and Machinery>>)

In order to facilitate the flow of materials in the puffing machine and reduce friction, the animal feed pellet mill should add a small amount of grease to the extruder machine. The general amount of grease is not more than 5% of the amount of material. The conditioned material enters the feed pelleting extruder machine to be extruded into pelletized feed. Then the expanded feed pellets are sent to the drying and cooling system of the animal feed processing line to cool down and dehumidify.

After drying and cooling, the expanded feed is sieved. Fine feed pellets and feed powder are sent back to the feed extruder for re-processing. Qualified expanded pellets are sent to the spraying machine for spraying oil, vitamins, flavor and color.

Decoding Expanded Animal Feed Processing Principles

Classification of Expanded Feed

Feed puffing process is a high temperature (up to 150 ℃) and a short processing time which is completed by the combined effect of moisture, heat, mechanical energy, pressure and other aspects. This process is used to condition the feed, which is continuously pressurized to extrude the pellets after a sudden pressure drop so that the pellet volume expands. According to the different methods of conditioning, expanded feed processing methods can be divided into two kinds: wet expansion and dry expansion.

Dry expanding process uses heat generated by friction, to warm the feed raw materials. Under the action of the extrusion screw, the feed is forced to pass through the die hole, while obtaining a certain pressure. After the feed is extruded out of the die hole, the pressure is suddenly lowered, the water evaporates rapidly, the feed forms a porous structure inside, and the volume increases, so as to achieve the purpose of expansion.

Dry expansion of moisture content is generally 15% ~ 20%. Wet expanding process principle is the same as dry expanding, except that the moisture content in the dry expanded feed is often higher than 20%, sometimes even more than 30%.

If you want to know more details about expanded feed making process and expanded feed processing principle. We are very happy to offer you our help.

Choosing Modern Feed Extruder Machines for Animal Feed Manufacturing Process

In the above, we have learned that the animal feed factory production of expanded feed can be divided into dry expanded feed and wet expanded feed. In the animal feed manufacturing process, dry expanded feed and wet expanded feed need to use different feed expansion machines. Dry type feed expanded machines and wet type feed expanded machines are two commonly used equipment for making expanded pellet feed in animal feed production lines. Now, we will learn about these two kinds of animal feed expanding machines and their characteristics together.

| GEMCO Feed Extruder Data for Your Reference | |

|---|---|

| Feed Extruder Machine Price: $1,850 | Feed Extruder Machine Capacity: 330-2000KG/H |

Dry Type Extruder Machine for Animal Feed Pellets

Dry-type Feed Extruder Machine for Sale

- Dry Type Feed Extruder Machine Working Principle: Under high temperature and high pressure, the feed is dried and extruded, and then quickly depressurized to make the feed expand rapidly. This process is usually completed in a relatively short period of time.

- Dry Extruder Machine Processing Characteristics: Dry expanded feed processing without adding a lot of water therefore saving energy and equipment costs of animal feed plant.

- Dry Type Expanded Feed Machine Application: It is suitable for the production of many kinds of animal feeds, including fish, poultry, livestock, pets and so on. Dry expanded feed is easier to store and transport.

Wet Type Extruder Machine for Animal Feed Pellets

Wet-type Feed Extruder for Sale

- Wet Type Feed Extruder Machine Working Principle: The feed is processed by adding the appropriate amount of water during the expansion process together with a high temperature.

- Wet Extruder Machine Processing Characteristics: wet type feed extruder pellet machine makes the expansion effect more significant, because water added fully dissolves the starch and other ingredients in the feed. However, compared with dry expanded feed, wet expanded feed may need more attention in storage and transportation.

- Wet Type Expanded Feed Making Machine Application: it is mainly used for making aquaculture feed as an excellent aquatic feed extruder machine. Because wet-expanded feed is more suitable for the digestion and absorption of aquatic animals. (Link to Fish Feed Pelleting Extruder Machine>>)

Wet Expanded Feed Pellet Preservation Methods: Wet expanded feed pellets preservation needs to be stored in a cool, dry environment, the use of sealed containers to isolate the air. Regularly check the status of pellet feed to ensure that there is no odor or deterioration. Reasonable management of inventory, adhering to the principle of first-in-first-out.

GEMCO Partnership: Blueprinting Your Path to Business Triumph

Complete Animal Feed Extrusion Production Line for Sale

At GEMCO, we stand at the forefront of animal feed processing with nearly 30 years of expertise, exporting cutting-edge animal feed manufacturing machinery to various countries, including the UK, Australia, Vietnam, Thailand, South Africa, Indonesia and so on. As a feed machine manufacturer, we pride ourselves on delivering feed processing solutions that help our clients achieve success with their animal feed business plans.

If you need any help, you can contact us directly. Let your success start with GEMCO!