Upgrade Goat Feed Pellet Macking Machine: High Profits & Healthy Goats

Goats/sheep, one of the most common livestock animals kept by farmers and in commercial farms, are an excellent source of meat, milk, and fiber. However, since goats/sheep are ruminant animals and they a four-chambered stomach. Therefore, the food for goats is required with balanced nutrition and can be digest easily.

Starting a Animal Feed Making Business for Goats/Sheep

Generally, the food for goats can be included with grass/alfalfa, grains, minerals, vitamins and more. But, in most cases, it is really inconvenient to measure and mix all the needed materials for the diet for goats. Fortunately, with the development of animal feeds industry, feed pellets offer a best way for goat feeding since goat feed pellets can included all the necessary nutrients, can be storged longer and can be easy to eat and digest. That is why more and more goat keepers or commercial goat farms tend to buy goat feed pellets. (Read more: Making Alfalfa Pellets for Animal Feeds >>)

Starting A Feed Pellet Making Business for Goat/Sheep and Other Animals

Since there are an increasing demand for goat feed pellets, it is profitable to set up a professional animal feed pellet productuion plant to produce high quality goat feed pellets. If you are new in this industry, just take easy, GEMCO will help you to get the most suitable goat feed pellet production plan, contact us any time to get latest business plan for commercial goat feed pellet making. Here, we just simply introduce the goat feed pellet production process and the hottest sale goat feed pellet making machines in the market. Then, you may have a clear idea on how to make goat feed pellets and how much would it will cost? If you have any questions, just contact us without hesistation, we are always here for you!

Complete Animal Feed Pellet Plant for Goat Feed Production

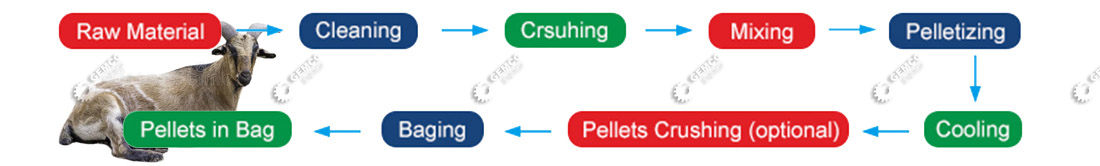

Goat Feed Pellet Production Process

Goat feed pellets production involves several steps, starting from selecting the right ingredients to packing the finished pellets for storage and distribution. But, this process is not absolute and can be adjusted according to specific needs.

Goat Feed Pellet Making Process

- Prepare Raw Materials: Animal feed pellet making needs various ingredients. For goat feed pellets making, the common ingredients have corns, soybean meals, alfalfa, wheat bran, rice bran, and more. In addition, some other nutrients are also necessary for goat feed processing, like protein, carbohydrates, fats, vitamins, and minerals.

- Grinding and Mixing: Prepared raw materials are then ground/pulverized and combined in an appropriate proportions to create a balanced diet. Grinding process ensures that the ingredients are the appropriate size that is suitable for pelletizing process of feed pelletizer. A feed mixer is used to uniformly combine the ingredients, ensuring that each pellet contains the same amount of nutrients.

- Feed Pelletizing: The processed ingredients are then transferred to animal feed pellet mill, which uses a die and rollers to compress and shape them into pellets of the desired size and shape. The pelletizing process uses heat and pressure to ensure that goat feed pellets are sterilized, pathogen-free, and easily digestible. Pelletizing is the core and key process for goat feed pellet making. And, choosing a reliable and efficient feed pellet mill is especially important to save cost and improve production.

- Pellets Cooling & Screening & Packing: After goat feed pellets are manufactured, they are cooled to reduce their temperature and moisture content. The pellets are then screened to remove any damaged or insufficient pellets, ensuring that only pellets of the highest quality are stored and distributed. The final stage involves packaging pellets in bags or containers for simple storage and transport. For some small scale goat feed pellet production or home use goat feed pellet making, these processes are optional. Buyer can choose it or not based on their specific needs and budget.

Choose Right Goat Feed Making Machines at Reasonable Price

In today’s market, there are various types of goat feed pellet making machines, ranging from mini scale to industrial scale, and the most popular ones are flat die type and ring die type. And, the selection of goat feed pellet making machine or goat feed pellet production line will depend on the production volume and budget.

- Flat Die Feed Pellet Mill - Small Goat Feed Pellet Making Machine

Flat die feed pellet mill is designed to use a flat die to compress and shape the raw materials into pellets. The flat die feed pellet machine operates by feeding the raw materials through a hopper into the pelletizing chamber, where the flat die and rollers compress and shape the materials into pellets. The pellets are then discharged through a chute. It is more suitable for small animal feed pellet production line, including home use, farm use or small scale pellet making manufacturer. Its price is relatively cheap in the market and its capacity is also relatively small. (Related order: Small Poultry Feed Making Machine to Nigeria >>)

Small Goat Feed Pellet Making Machine for Sales

- Ring Die Feed Pellet Mill - Commercial Goat Feed Pellet Making Machine

Ring die feed pellet machine is designed to use a rotating die to compress and shape the raw materials into pellets. It operates by feeding the raw materials through a feeder into the pelletizing chamber, where the rotating ring die and rollers compress and shape the materials into pellets. The pellets are then discharged through a chute. Ring die feed pellet machine is more suitable for commercial or large scale animal feed production that requires consistant output. (Related order: 2TPH Poultry Feed Plant to Indonesia >>)

Commercial Goat Feed Pellet Plant at Low Investment

Both these two types animal feed pellet mills are suitable for both goat feed pellet making and other animal feed making, like chicken, cattle, pig, fish feeds, and more.

In addition to the type of machine, other factors to consider when choosing a goat feed making machine include the power source, production capacity, pellet size range, and maintenance requirements. Overall, choosing the right goat feed making machine is crucial for ensuring high-quality pellets and efficient production. It is essential to consider the scale of production, budget, and specific needs when selecting a machine. (You may also like: How Much a Feed Pellet Mill Price is?)

Reliable Goat Feed Pellet Making Machine Supplier – GEMCO

To ensure the high efficiency of goat feed pellet production and the quality of goat feed pellet mill for less maintainance, it is essential to find a reliable animal feed pellet machine manufacturer. GEMCO has been in the feed pellet machine industry for over 20 years and has a wealth of experience and expertise in designing and manufacturing high quality animal feed pellet machines. We can offer a wide range of machines and provide customized solutions to meet specific needs for your goat feed pellet making business. We also offer excellent after-sales service, including installation, training, and technical support, to ensureyou get most out of our machines.