Small Feed Pellet Line

What is small feed pellet line?

Small feed pellet line is also called mini feed production line or mobile feed pellet line which is used to process animal feeding pellets. Our small feed pellet line is can produce 2-8mm of feed pellets, the yield is 0.6-3t/h. This feed complete machine set is widely used in small and medium size of feed pellet production line, livestock farms and individuals who raise animals, etc. The feeds are suitable for pigs, cattle, sheep, rabbits, chickens, ducks, geese and other aquatic organisms.

Function of Small Feed Pellet Line

Small feed pellet line has a way to grinder, mixer, convey, pelletizer, cooler in one means, which can grind the maize and bean pulp by the grinding machine, then mix with the wheat bran, bone meal, microelement, vitamin and other raw materials to make the complete feed. Those complete feed is made into pellet feeds by feed pellet mills. The pellet feeds can be packed directly after the screening and cooling.Feed Pellet Making Process

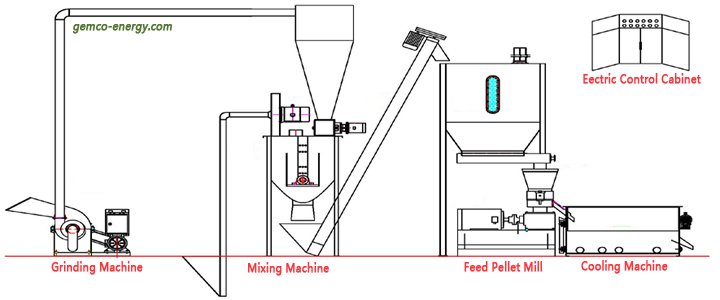

feed pellet complete machine set flow chart

As the picture, the corn and bean cake are ground by the self-suction grinding machine. The materials that don’t need to be ground like wheat bran, bone meal, microelement, vitamin directly go into the mixing machine from the feeding port. All the materials are mixed uniformly and sent to the hopper then sent into feed bin by screw conveyor. After that, the materials go into feed pellet mill equipment evenly from the feeding port and are produced into pellets. Those pellets then go into the cooling machine. Under the function of ID fan, the pellets are cooled to the temperature that is not over 5℃ than the room temperature. The cool pellets are screened by the vibrating screen, then they can be packaged.

Note: We can customize the feed production line according to the customer's requirement.

Performance of Small Feed Pellet Line

- Compact structure, occupying small area, low requirement to the plant, low investment.

- Easy to install, no need for civil engineering and welding at scene. The feed pellet machine can be used directly after the connection with low installation cost.

- Continuous production, easy operation, small labor capacity, needing less stuff, the whole production line only needs 1-2 persons and the production cost is low in the later period.

- Wide application, it can produce both livestock feeds and fish feeds, which is suitable for the small scale and medium scale feeding production plant, livestock farms and individuals who raise animals.

Successful Case of Small Feed Pellet Line

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!