New Type Double Headed Punching Briquette Machine for Sale

Double Headed Punching Briquette Machine is the new briquette machine researched and developed by our company. This molding machine uses the punching principle of the crank connecting link to work, and the pressure can be more than 300 tons. It can adapt to each kind of biomass material, and the processing effect is perfect. Each moving part of the double headed punching briquette machine is forced to be lubricated by the oil pump and cooled by the cooling water. That is to make sure the normal running of the equipment.

| Model | GC-MBP-2000 |

|---|---|

| Main parts | Punching Briquette Machine |

| Feed box | |

| Lubrication pump | |

| Control cabinet | |

| Working Conditions | 380V 50HZ (temperaturer: -15℃~40℃) |

| Raw Material Moisture Content | Less than 20% |

| Capacity | 1.2~1.5Ton/Hour (different biomass materials have different output) |

| Density | 0.8~1.2Ton/m3 |

| Feeding speed control | Frequency conversion |

| Die service life | 300-600T(different materials have different die service lives) |

| Briquettes Diameter | 18mm, 30mm, 50mm, 70mm |

| Power of main engine | 55KW |

| Weight | 8000kg |

| Overall dimension | 3300x1500x1460 mm |

Finished Products

Video of punching briquette machine

φ70mm briquettes

φ30mm Briquettes

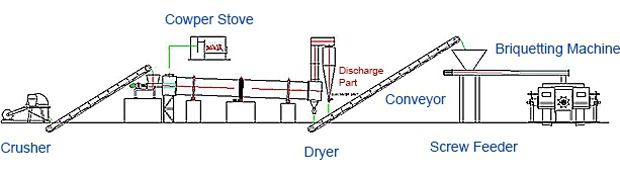

Building a Punching Briquette Line

Why choose Double Headed Punching Briquette Machine

Double headed punching briquette machine is mainly used to compress the pulverized farm waste, barks, sawdust, twigs, wood, rice straw, rice husk, and furniture factory dust and other biomass raw materials into briquettes under the situation of suitable pressure, temperature, granularity and moisture content to improve the combustible performance.The biomass fuels produced by this double headed punching briquette machine is a new kind of reproducible and environment-friendly fuel, which has the advantages of cleanness, high calorific value and high combustible rate, etc. It can be used in furnace, boiler, electric stove and so on. Besides, in many areas, it can be a substitute goods of coal and natural gas. The formed biomass fuels can be also carbonized into charcoal to meet the requirement to high standard energy of people.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!