Special Designed Small Chicken Feed Mill Plant for Tanzania

With the improvement of living standards, global residents’ recognition and demand for pollution-free food, green food and organic food have greatly increased. Changes in market demand have also placed higher requirements on the production and product quality of chicken feed companies. The chicken industry has become a breeding industry that many countries in the world pay attention to and value. Based on market demand, the development of the chicken industry has broad market prospects.

Chicken Feed Making Machine Supplier

Tanzania has a long history of animal husbandry development and rich pasture resources. About 40% of the entire territory has good conditions for animal husbandry development. In addition, the Tanzanian government attaches great importance to the development of animal husbandry, and more and more people invest in chicken plants . Some chicken farmers will buy feed, which will increase the cost. Many people choose to configure their own feed, but due to the limitation of the situation, the farmed chickens cannot get sufficient nutrition. At this time,the chicken feed mill plant is needed.

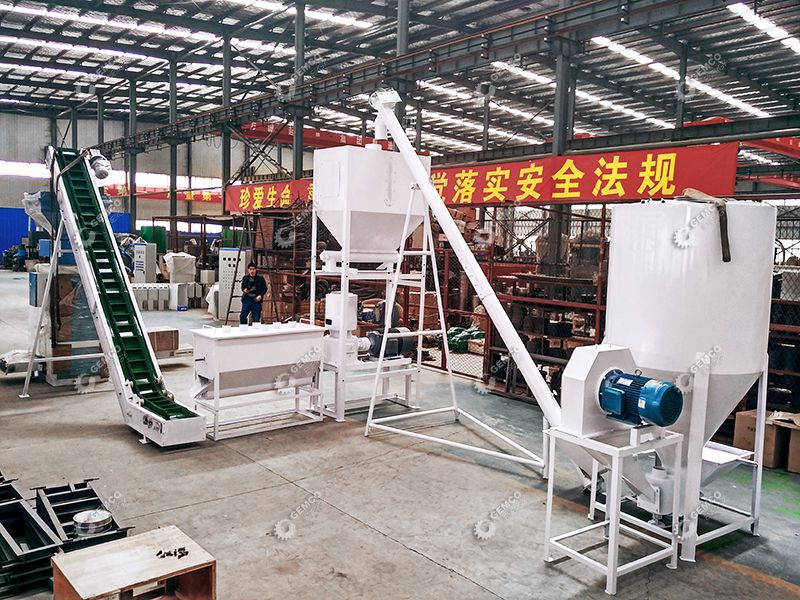

Small Chicken Feed Mill Plant To Tanzania

Small chicken feed mill plant for Tanzania is professionally designed for making chicken feed pellet in Tanzania, which is mainly composed of a series of equipments including hammer mill, mixer, conveyor, storage silo, feed pellet machine, pellets cooler and packing machine.

According to the actual situation in Tanzania, we equip our ZLSP series flat die feed pellet machine in this small chicken feed mill plant which is the most suitable equipment for producing chicken feed pellet, able to make almost all kinds of powder raw materials for chicken diet into feed pellets, including crops like corn, wheat, bran, sorghum, cassava, rice, soybean etc, oil meals like soybean meal, cottonseed meal, peanut meal etc and vitamins agents etc. Due to the small scale of chicken farms in Tanzania, this small chicken feed mill plant is designed to produce 600-800kg chicken feed pellet in the size of 3mm to 4mm per hour, meeting the daily demand of chicken.

Chicken Feed Pellet Machine Model And Parameters

ZLSP Flat Die Feed Pellet Machine Technical Data

| Model | Power | Capacity (kg/h) | G.W./N.W. | Packing Size |

|---|---|---|---|---|

| ZLSP-D 120B | 3kw (3phase)/2.2 kw (Single phase) | 60-100 | 80/100 | 750x320x680 |

| ZLSP-D 150B | 4 kw (3phase) | 90-120 | 95/110 | 800x450x700 |

| ZLSP-D 200B | 7.5 kw (3phase) | 200-300 | 200/230 | 1650x820x1200 |

| ZLSP-D 230B | 11 kw (3phase) | 300-400 | 290/320 | 1050x480x930 |

| ZLSP-D 260B | 15 kw (3phase) | 400-600 | 320x360 | 1180x540x1000 |

| ZLSP-D 300B | 22 kw (3phase) | 600-800 | 350/380 | 1240x540x950 |

| ZLSP-D 150C | 4 kw (3phase) | 90-120 | 105/125 | 1000x480x780 |

| ZLSP-D 200C | 7.5 kw (3phase) | 200-300 | 210/230 | 1050x550x830 |

| ZLSP-D 230C | 11 kw (3phase) | 300-400 | 290/320 | 1200x560x950 |

| ZLSP-D 260C | 15 kw (3phase) | 400-600 | 340/370 | 1240x580x1000 |

| ZLSP-D 300C | 22 kw (3phase) | 600-800 | 425/465 | 1300x620x1100 |

| ZLSP-D 120A | 8 Hp | 60-100 | 120/140 | 900x500x730 |

| ZLSP-D 150A | 8 Hp | 90-120 | 180/220 | 1000x500x750 |

| ZLSP-D 200A | 15 Hp | 200-300 | 210/240 | 1460x750x900 |

| ZLSP-D 230A | 22 Hp | 300-400 | 280/310 | 1560x850x1000 |

| ZLSP-D 260A | 30 Hp | 400-600 | 330/360 | 1200x500x1070 |

| ZLSP-D 300A | 55 Hp | 600-800 | 410/450 | 1220x600x1000 |

| ZLSP-D 150P | ≥8 Hp | 90-120 | 105/125 | 900*540*1020 |

| ZLSP-D 200P | ≥15 Hp | 200-300 | 210/230 | 1000*540*1020 |

| ZLSP-D 230P | ≥22 Hp | 300-400 | 290/320 | 1000*540*1020 |

| ZLSP-D 260P | ≥30 Hp | 400-500 | 340/370 | 1050*540*900 |

| ZLSP-D 300P | ≥55 Hp | 500-600 | 425/465 | 1100*540*1000 |

The above are the specifications and parameters of the flat die pellet machine manufactured by GEMCO Machinery. If you are interested in investing in a small poultry feed mill plant, the above information can help you better choose products according to your needs.

Small Chicken Feed Pellet Mill Working Video

The above is the working video of the small chicken feed pellet machine manufactured by GEMCO Machinery. It can be seen from the video that our chicken feed flat die pellet machine has stable production performance, which can help you achieve continuous and uninterrupted processing needs at low cost.

Chicken Feed Processing Market Overview in Tanzania

We know that Tanzania is not a developed country, which develops agriculture as the economic domination, thus there are variety of raw materials which can be used for making chicken feed pellet, such as, soybean, wheat, corn, rice bran, peanut, rice husk and kinds of meals including maize perm meal, bean meal, cottonseeds meal and rapeseed dregs etc. Therefore, the rich raw materials give the development of chicken raising a stable foundation in Tanzania.

Rich Materials For Making Chicken Feed Pellets

Moreover, in Tanzania, chicken production is an essential source of animal source and income, providing a good opportunity get higher profit for the commercial chicken production enterprises. And, chicken dominates the animal husbandry of Tanzania. It is reported that 86% of livestock fed in Tanzania are chicken and 48% of families feeds chicken as their daily meat nutrition source, which indicating the importance of developing chicken in promoting livestock meat development, reducing the poverty and improving nutrition. With the bright future prospect, small chicken feed mill plant Tanzania is also a worthy project for investment.

poultry industry in Tanzania

Advantages of Small Chicken Feed Mill Plant Tanzania

-

Small chicken feed mill plant for Tanzania adopting small size machines, is designed with reasonable and compact structure, covering a small area, even you can set it up in your back yards.

-

With high quality materials, all the machines which are equipped in small chicken feed mill plant can serve for longer time, easy to care and maintain, reducing the maintenance cost.

-

Through complete processing, the finished chicken feed pellet has bright and smooth surface, high density, better palatability, easy to be digested by chicken, avoiding the chicken being picky.

-

The detailed processing of small chicken feed mill plant in Tanzania can be adjusted properly according to the actual requirements of the customers.

-

In the vital pelleting processing, the feed pellet machine structure has been optimized by adding the reinforcing rib and increasing the casting thickness, thus strengthening the machinery strength, stopping the problem of machine shell breaking.

-

Safe electricity control is equipped in this small chicken feed mill plant Tanzania, which meets the CE operation system, the emergency button can stop the production at the urgent condition.

-

Due to the strict and standard production and technical management, the consistency and interchangeability of all the components have been guaranteed, the customers can choose the components without worries.

How to Start a Small Chicken Feed Factory Processing Project?

Because chicken pellets have improved the feed efficiency in raising chickens, the production of eggs and chickens has been significantly improved, so it has become more and more popular. In recent years, more and more chicken farms have established their own chicken feed production lines and started local chicken feed pellet sales business. So, how should those who invest in the chicken feed processing industry for the first time build a small-scale chicken feed pellet factory at low cost?

- Conduct market research on chicken feed processing plants

1. The local market environment.

2. Development and scale of aquaculture industry.

3. The number and scale of chicken feed production enterprises, and chicken feed pellet manufacturing equipment.

- Receive training and technology for chicken feed pellet formulation

1. Know the formula of chicken feed pellets.

2. Understand the raw materials and how to buy raw materials.

3. To understand the different growth cycles of chickens requires changing different formulas.

- Develop a business plan for a chicken feed pellet processing plant

1.Determine the type of feed that needs to be produced.

2.Determine the scale of production, for example: 1 ton per hour, 10 tons per hour, etc.

- Find a good location for your chicken feed pellet machine

Find a suitable land to fill the chicken feed pellet processing plant with electricity and water.

- Purchase of equipment and machinery for chicken feed processing plants

Contact a professional chicken feed pellet machine manufacturer to consult and determine the process plan and all equipment list of the chicken feed pellet production line in detail. Here GEMCO Machinery suggests that you must find a professional chicken feed pellet machine manufacturer, preferably a qualified chicken feed pellet machine manufacturer and exporter.

If you have any questions about our small chicken feed mill plant for Tanzaniaor want to build your own poultry feed factory, please fill in the message form below to contact us for more detailed information, We are looking forward your message!