Ethiopian Customer Visiting Our Charcoal Briquette Production Line

As the charcoal fuel becomes more and more popular with its high heat value and low ash, many people choose to make charcoal fuel for using by themselves, or selling charcoal fuel, at the same time, the equipment for making charcoal is going to people’s view.Recently, our Ethiopian client came to us for the second time, and this time he brought an Australian investor, with the purpose of visiting our charcoal briquette production machinery in our factory. Last time, this Ethiopian client has purchased our charcoal briquette production line with 5 screw charcoal briquetting machines connected and other related equipments. This time, he wanted to show the Australian investor our factory.

Visiting Our Charcoal Briquetting Machine Factory

After their arrival, our manager in charge of this project led them to our charcoal briquetting machine factory. The personnel of the factory showed them around the workshop and the machinery which has been finished manufacturing purchased by our Canadian customer before. In this period, the factory personnel explained the working principle of the key equipment, the screw charcoal briquetting machine and introduce the procedures of the charcoal briquette production line briefly.

(GEMCO Charcoal Briquette Production Line Factory)

(Ethiopian client and Australian investor are seeing screw charcoal briquetting machine)

Screw Charcoal Briquetting Machine for Sale

This screw charcoal briquetting machine is our newly researched and developed type, which adopts the screw principle with using the propeller to push the raw materials forward to the briquetting chamber. The screw charcoal briquetting machine produces the charcoal briquette with solid cylindrical or hollow-center shapes. Due to the carbonizing surface of the finished charcoal briquette, the screw briquetting machine is very suitable for making charcoal fuel.

(Finished manufacturing screw charcoal briquetting machine for Canadian customer)

- Output: 300-350kg/h

- Motor power: 22kw

- Finished briquette size: 8-70mm

- Inner diameter: 18mm/16mm

- Briquette density: 1.3T/m3

- Overall Dimension: 1500*1200*1600mm

- Weight: 780kg

Visit charcoal briquette factory that has been running for 10 years

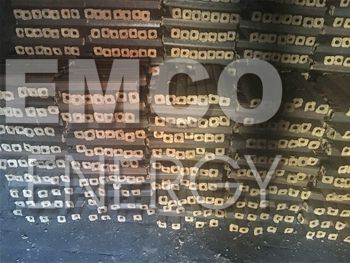

Except of showing the clients around the factory, our manager also led them to visit the charcoal briquette production line of our domestic customer. The domestic customer told them this charcoal briquette production line was purchased in 10 years ago, and it still was running pretty well. the raw material for this production line sawdust, the equipment including the drum screener, dryer, material separating auger, 3 pieces of charcoal briquetting machine and dust collecting equipment etc. The customer also showed them the earth kiln built by themselves.

(Earth kiln and wood briquettes waiting to be carbonized)

(The finished charcoal briquettes produced by this 10-years charcoal briquette production line)

Process to Make Charcoal Fuel in Charcoal Briquette Production Line

- At the first stage, you should prepare your raw materials well by keeping the moisture content in 12%-15%, and the size of the raw material had better be processed into 3mm. What machines you need to use are the hammer mill, dryer, besides, if your raw material is wood log, the chipping machine should be equipped as well.

- After preparing the raw materials, it is time to briquetting which is the key of the charcoal briquette production line. Through the charcoal briquetting machine, the loose raw materials will be compressed into solid density briquette, and the size of briquettes can be decide by adjusting the size of the forming sleeve.

- The fresh finished charcoal briquette has a high temperature, which has to be cooled by the cooler. Or if you make charcoal briquette for self-use, you can decrease the temperature by putting them in a cold place.

- At last, put the briquettes into the carbonizing kiln and adjust the temperature of the kiln, the charcoal fuel is finished.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!