500KG/H Vegetal Charcoal Briquettes Production Project in Ethiopia

- Project Location: Ethiopia

- Capacity: 500kg/h

- Raw Materials: Wood Meal, Bamboo Meal and Bamboo Waste

- Final Products: Vegetal Charcoal Briquette

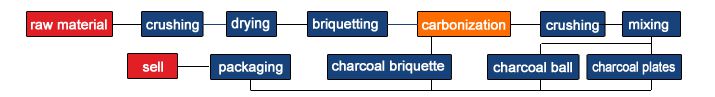

- Pelletizing Process: Crushing → Drying →Briquetting → Carbonization → Crushing → Mixing → Packaging

In July 2019, the 500kg/h biomass vegetal charcoal briquette project established by GEMCO in Ethiopia was completed and put into production. This project is composed of three process: briquetting process, carbonization process, charcoal briquette ball and carbonizaed briquette plates production process.

Onsite Construction Drawing: Making wood briquettes and Making chaocoal briquettes

Our customer from Ethiopia owns a big toothpick production factory, producing a mass of wood meal, bamboo meal and bamboo waste everyday, the raw materials for producing vegetal charcoal briquettes is abundant. Based on the actual condition and the requirement of our customer, GEMCO has built the following process for him:

Biomass Vegetal Charcoal Briquettes Production Process

Charcoal Briquette Production Line Installation and Commissioning Photos

The equipment used in the whole charcoal production line is: hammer mill, dryer, charcoal briquette machine, carbonization furnace, crusher, mixer, coal briquette press, packing machine.The following is a detailed introduction of the on-site installation and commissioning of this coal briquette briquetting equipment by the GEMCO professional technical support team.

The briquette making machine produced by GEMCO Machinery solves the shortcomings of ordinary wood briquette machines for the high water content of the wood chips and the rapid wear of the forming mold. The equipment has the characteristics of low power consumption, high production efficiency, long mechanical operation life and low maintenance rate. Briquettes can replace conventional energy sources such as coal and oil, and are widely used in industrial production, government agencies, enterprises and institutions, urban residents' heating, residential cooking and high-end fireplaces. It can also be used as a raw material for power generation in biomass power plants.

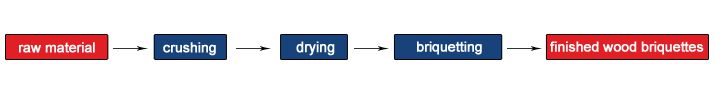

Briquetting Process: Making Wood Briquettes

Put the bamboo waste into the crushing machine to crush them into powder, and the bamboo and wood powder with high moisture content should be put into the drying machine for decreasing the moisture content. Then the processed raw material enters the charcoal briquette machine to be formed. The finished vegetal briquette is waiting to be carbonized after natural cooling.(Related Project:500kg Per Hour Biomass Briquetting Plant In Russia>>)

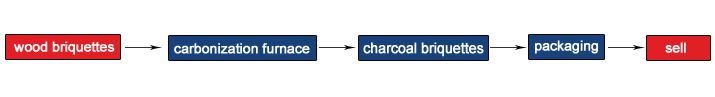

Carbonization Process: Making Charcoal Briquettes

When the finished wood briquettes enter the furnace tank, 4 kiln of charcoal briquettes can be fired at one time. Then the charcoal briquette is finished to be packed for sale. Our customer chose the woven bag package for sale in local markets.

-

Special Statement:

The main equipment in carbonization process includes carbonization furnace, cooling system and air circulation system. The heat is needed to supply only when the initial carbonization. When the carbonization processes normally, the carbonization furnace will produce the flammable gas which is collected to supply energy for the carbonization furnace, thus saving plenty of energy consumption.

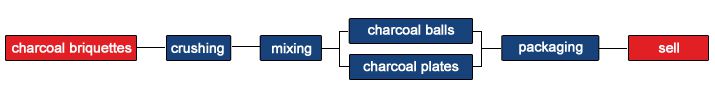

Vegetal Charcoal Briquette Ball and Plate Process

Finished vegetal charcoal briquette enters the crushing machine for crushing into charcoal powder, and mix the powder and adhesive completely by the mixing machine. One part of the processed raw materials enter the ball press machine(coal briquette press) to be formed into ball shapes, and the other part enter the tablet pressing machine(shisha charcoal briquette press) to be formed into plate shape. Different shape of carbon briquette balls and tablets are packed for sale.

Since the foundation in 1997, GEMCO has designed and built hundreds of biomass pellet and briquette production projects. Different countries have different requirements and conditions, we design and build the production line based on the actual condition and user’s requirements. Want to build your own vegetal charcoal briquettes project? Contact us please!