Operation Method of Dry Distillation Carbonization Stove Machinery

Dry Distillation Carbonization Stove is the most advanced charcoal dry distillation equipment, designed and formed by our company through repeated test, improvement, being the most advanced distillation carbonization equipment, truly realizing smokeless carbonization. The purified smoke is no only used for carbonization, the extra smoke is also used for raw material drying, home heating and cooking etc.Carbonization stove machinery is easy to operate to make charcoal from biomass raw materials. Common carbonization raw material is wood, sawdust, tree branch, coconut shell, bamboo bits, palm shell, olive husk, wood briquettes, cob etc.

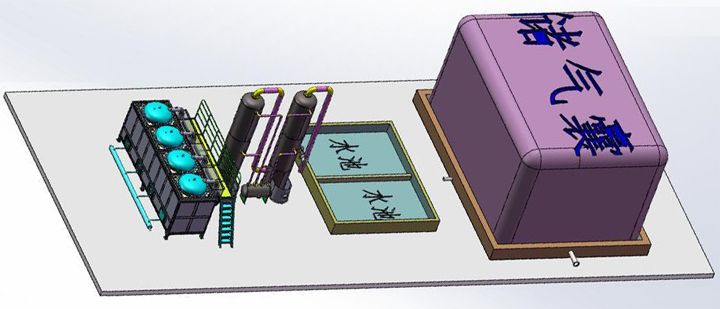

Dry Distillation Carbonization Stove Composition

Every set of furnace equipment is composed of one set of furnace with 4 holes, 12 sets of furnace pipe (its wall texture is Q235B iron with thickness of 6mm, and the bottom texture is Q345R capacitor plate with thickness of 8mm), 2sets of smoke purifying system, 1 set of gas transmission system and connecting flange, alloy steel water pump, high pressure fan, pipe valve is each set.Carbonization Process

Actually, carbonization process is the pyrolysis process that the compressed briquette is heated and decomposed in the carbonization furnace under the condition of no air. Except of the solid charcoal briquette is produced, the liquid products like wood vinegar liquid and wood tar, and gas products like wood gas are also produced. The pyrolysis process mainly consists of the following steps:- Drying step: the temperature of this step is under 120-150℃, the pyrolysis processes slowly, mainly is drying, water evaporation, meanwhile the chemical briquette is almost not changed. What need to attention is that the gas exhausting step had better no too fast.

- Pre-carbonization process: when the temperature gets to 150-270℃, the xylon start to decompose. The unstable composition like hemicellulose inside of the xylon starts to decompose into carbon dioxide, carbon monoxide and other gases, meanwhile a small amount of acetic acid is produced as well.

- Carbonization process: when the temperature gets to 275-450℃, the xylon decomposes rapidly. Firstly the cellulose decomposes thermally(with the temperature of 280-290℃), then the lignin starts to decompose to generate a large amount of decomposition product (with the temperature of 350-450℃). In the gases, the carbon dioxide and carbon monoxide gradually decrease, while the hydrocarbon like methane increase. In the liquid matters, there are a large amount of acetic acid, methyl alcohol and wood tar oil. Meanwhile a large amount of heat is produced. Thus, this process is also called as exothermic process. What need to pay attention is that the carbonization speed in carbonization stage should not be too fast.

- Calcination process: when the temperature gets to over 450℃, large amount of charcoal is needed for calcination, to discharge the volatile substance which is left in the wood, at this time, there is little liquid produced but more gas.

Carbonization Time (from firing to stopping)

- A: low-temperature carbon: 10 hours.

- B: middle-temperature carbon: 12 hours.

- C: high-temperature carbon: 14 hours.

Carbon Temperature (based on the tested temperature)

- A: low-temperature carbon: 360℃(the actual temperature is higher than 450℃).

- B: middle-temperature carbon: 450℃(the actual temperature is higher than 600℃).

- C: high-temperature carbon: 500℃(the actual temperature is higher than 700℃).

Carbonized Product

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!