How to Use and Choose Mini Feed Pellet Machine

Pellet feed is produced through high temperature and disinfection, possessing more advantages than powder feed, thus having plenty of applications in the actual production. Mini feed pellet machine, belonging to pellet feed making equipment, is designed with various types, which is auditable for processing different raw materials. Therefore, it is very important for improving working efficiency of mini feed pellet machine to choose a suitable type.Tips for Choosing Mini Feed Pellet Machine

For choosing feed pellet machine, what raw material should see to process above all. If concentrated feed is to be processed, both of the flat die or ring die pellet machine are suitable; while to process the grass powder material or grass-grain combined feed, it better choose the flat die feed pellet machine, which means the mini feed pellet machine. Due to connecting rod shaft gearbox driving the motor, anti-overload capability is strong. And the main components of small feed pellet machine like pressing roller, pelleting die are processed by superior alloy steel through high frequency hardening, featured with high abrasive resistance, having 5~7 times of longer lifetime than the same type machine made from common materials.Choosing the suitable mini pellet machine according to the feeding scale and feed consumption. Generally, 200 type mini feed pellet machine is suitable for individually home farming due to the features of adopting household lighting electricity for production, convenient moving and easy operation etc.

Application Method

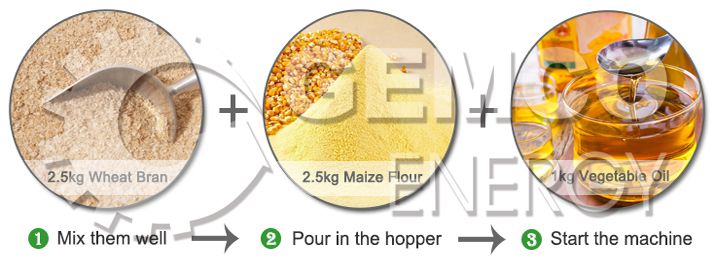

- Running-in for new mini feed pellet machine: preparing 10-20kg of mixed powder materials with 5%-10% edible oil added, rub the oil blocks together by hand. Add the feed first, after starting the machine, adjust the pressing roller bolt by hand until the material is discharged normally. When the materials with oil has been recycled for 3-5 times inside of the machine, add dry materials gradually (the materials with oil can not be fed the animals after extraction. And the new machine has no need to running-in after running in once.)

- Adjustment of pellet feed length. The pellet feed length can be adjusted through adjusting the cutter installed in the outlet hole.

- The finished pellet feed has relatively high temperature, needing to be stored in a well-ventilated place, it can be stored into bags when it is cooled to the indoor temperature.

Matters Needing Attention in Operation

- When the new mini feed pellet machine is used for the first time, it must be worn in, otherwise it can not be used normally, or the pelleting effect is not good.

- When the machine is connected to the lighting supply, the wire should be the copper wire with no less than 4m2, and the meter uses 5-10A.

- When the machine is running, the hand is forbidden to enter into the feeding port.

- Before starting the machine, some materials should be added into the machine. When shouting down the machine, a few materials should be left in it, to avoid the pressing roller touching the pellet die resulting idling.

- If something is blocked in the machine, stop the machine immediately. Restart the machine until the roller is pressed tightly to loosen the bolt.

- When the feed pellet machinery is stopped for every time, the adjusting pressing roller should be loosened.

- After the mini feed pellet machine is used for a few while or a certain number of pellets has been pressed out, if the finished pellets are broken or not solid, the mixed materials should be turned around from the upper layer to the lower layer, and add 2%-4%water into it.

- Check the belt tightness, avoiding the machinery output is low, and belt slipping.

- When the machine is used next time, it should work with low load for 40 hours, then the gear oil in the gear box should be replaced. Later, replace it for every 100 hours regularly, and all the bearings should be added with lubrication grease regularly.

- It is normal that the pellet machine works continuously, with the electric motor temperature reaching to 70℃。

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!