Biomass Energy at Your Fingertips: The Power of Wood Pellet Machines

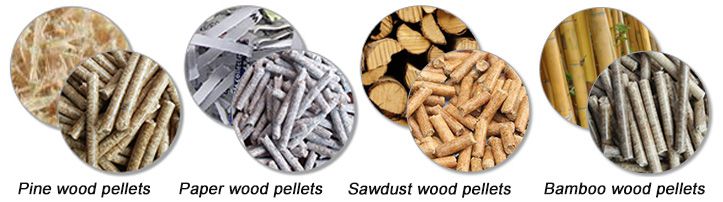

Wood pellets are the biofuels made from the compressed sawdust and similar industrial waste products. Commercial wood pellet manufacturing plants are now providing more wood pellets globally as the consumption of this biofuel is increasing due to an increase in the prices of other fuels. The world is trying to take control of global warming, so, now governments are putting more emphasis on the consumption of eco-friendly fuels over fuels like petroleum, coal, etc. (Read more: Biomass Pellet Making Machine >>)

Wood Pellets Manufacturing

Wood pellet has gained its popularity as one of the mostly used renewable fuel sources in recent years; as a result, wood pellet manufacturing has become a sunrise industry, which means it is promising and profitable. Now in many countries, there are wood pellet manufacturing plants. It can make pellets from wood shaving, sawdust, wood chip, branches, logs, and so on.

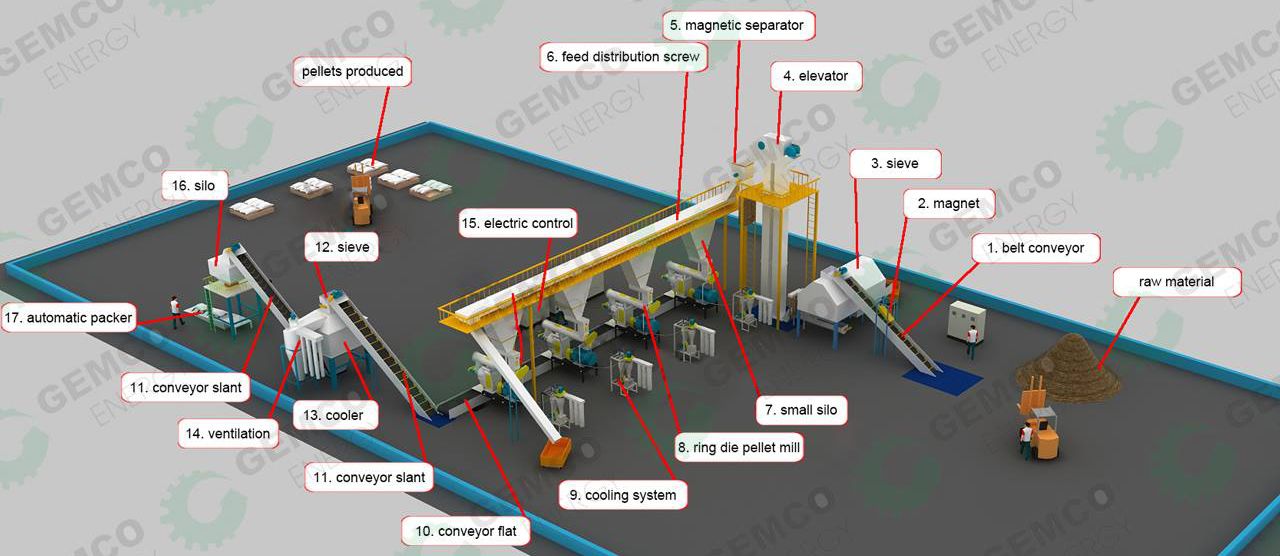

Wood Pellet Manufacturing Equipment & Process

The production of wood pellets involves a series of process and equipment to ensure the quality of final wood pellets. The manufacturing of wood pellets includes the following steps:

Wood Pellet Manufacturing Process

- Raw Material Crushing: Materials such as wood chip, wood shaving need to be processed by crushing machine into 2-5mm in diameter; sawdust with such diameter does not need to be crushed; but wood log, tree branch shall be chipped by wood chipper before crushing.

- Screening: Sometimes the sawdust or wood powder may contain impurities like stones or metal scraps that can break the wood pellet machine. If the raw material does not contain impurities, the screener is unnecessary in the wood pellet manufacturing business plan.

- Wood Powder/Sawdust Drying: The wood, especially fresh wood contains moisture much higher than 20%, is unsuitable for pelletizing. As a result, the wood sawdust shall be dried by professional equipment, like sawdust rotary dryer.

- Wood Pellet Manufacturing: Then, the processed raw material is fed into the pellet mill machine, and pellets will go out from the outlet. (Read more: GEMCO Pellet Machine Price >>)

- Wood Pellets Cooling: For commercial production, wood pellets shall be cooled after they are produced. Then you can pack the wood pellets in small or large bags for sale or for storage.

Commercial Wood Pellet Manufacturing Equipment for Sales

Wood Pellet Machinery is the key part in the complete biomass pellet plant. Its quality determines the quality of wood pellets, so you need to keep an eye on choosing the proper wood pellet machine manufacturers. (Read more: How to Choose Your Own Fuel Pellet Mill >>)

As one of the world leading commercial wood pellet machine manufacturers, GEMCO has years of experience in researching and developing machines to manufacture wood pellets as well as other types of biomass fuels. For your specific raw wood material, GEMCO will choose the most suitable equipment for you, and the wood pellet making equipment will has the best compression ratio (which determines the quality of your wood pellets) for your raw material.

Wood Pellet Manufacturing Equipment Manufacturer

Customized Wood Pellet Manufacturing Business Plan

If you want to manufacture wood pellets or start wood pellet manufacturing business, it is wise to make a business plan first. The plan shall include your raw material, your capacity, your budget, your funds, your workshop, and so on. (Read more: Starting a Charcoal Briquette Business >>)

- The Raw Material Determines the Types of Wood Pellet Processing Equipment. While, the Capacity Determines the Model You Choose.

If you have soft wood as raw material, you choose large wood pellet machine or D-type small pellet machine; if you have hard wood as raw material, you choose large pellet machine or R-type small pellet machine.

- Your Budget and Funds Determines Equipment In Your Wood Pellet Manufacturing Plant. While, Your Workshop Size also Affects the Scale and Arrangement.

If you have sufficient funds, you can set up a complete wood pellet line; if you do not have too much funds, you can set up a small wood pellet mill.

If you are planning to start wood pellet manufacturing business, but have related knowlege about how to choose a right wood pellet manufacturing equipment, please contact us, we are professional, we can offer the customized plan based on your budget, help you to get the BEST equipment. You're welcomed to contact us at anytime. We will give you reply asap!

Wood Pellet Manufacturing Plant Installation Video

Buy High Quality Wood Pellet Manufacturing Equipment to Make Biomass Pellets Fuel: Hot Sale Wood Pellet Making Machines Offered by Wood Pellet Machinery Manufacturer or Supplier, Guide on Process of Wood Pellet Production and How to Start Wood Pellet Manufacturing Business with Limited Cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc..

Future Prospects of Commercial Wood Pellet Mill

If we look into the past decade, then according to stats annual growth of wood pellets has increased every year. Its growth was 19.5 million metric tonnes in the year 2012 and reached 35.4 million metric tonnes in the year 2018. Various factors have affected the production and consumption rates of wood pellets. The most common reason is that economies are thriving gradually which means they have more fuel needs today. So in order to meet those needs industries prefer biofuels as they are cheap and environmentally friendly. More and more commercial wood pellet manufacturing plants are being developed all over the world to produce more pellets according to the world’s demands.

Wood Pellet Making Equipment Installation

According to the studies, the estimated global wood pellet manufacturing market price was USD 9 million in the year 2017. Marketing experts have estimated an increase of 8.7% in compound annual growth rate (CAGR) from the year 2017 to 2027. Western Europe is the actual winner in this field as it is manufacturing wood pellets in large amounts and supplying to numerous countries to make its presence known in the market. America that has a global wood pellet market share of 7.8% comes after Europe in this field. The Asia Pacific and the Middle East and Africa are also estimated to play a major role in the wood pellet manufacturing in the near future.

There are numerous reasons that will cause an increase in the manufacturing of wood pellets in the future. In North America, an increase in the wood pellets consumption on commercial, industrial, as well as on domestic level is expected. It is because the prices of coal and petroleum fuels are increasing so people are moving towards wood pellets leaving the expensive fuels behind. In Western Europe, the government is putting much more focus on reducing carbon emissions as it is destroying nature slowly and causing issues like global warming, floods, etc. (Read more: Pellet Mill Canada >>)

The Canadian government is also making new regulations to decrease coal usage and increase consumptions of other heating sources such as wood pellets. They have planned to decrease the usage of coal by 12 million tons by the end of 2030 which will eventually boost the consumption and manufacture of wood pellets. As people rely on coal for so many reasons so when they will be asked to replace it with a better source they would come for the wood pellets sooner than later. So the world needs more commercial wood pellet manufacturing machine today as people are turning towards wood pellets for their basic needs.