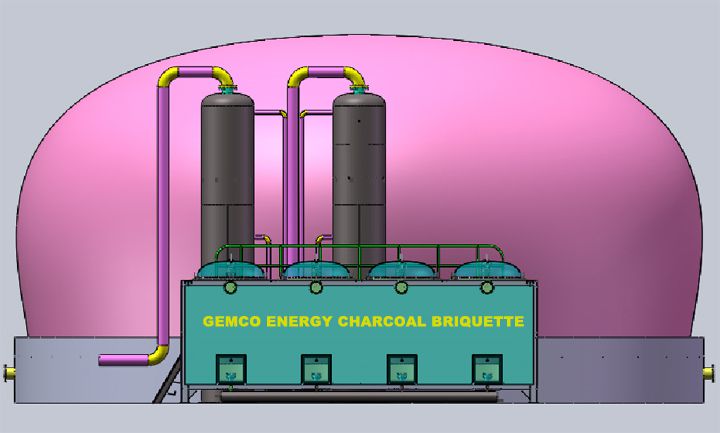

Carbonization Equipment

Carbonization equipment making kinds of biomass raw materials like wood, branches, wood chips, pillar, fruit shell or making mechanical briquette into carbon, mainly used in the charcoal briquette production line.Mechanism Charcoal Carbonization Equipment:

Smokeless Dry Distillation Carbonization Furnace

Carbonization is the indispensable part of the mechanism carbon production process. Biomass raw material is processed into biomass briquette by the screw briquette machine or other biomass forming equipment, or is processed into charcoal briquette, pellet, powder etc through carbonization process by carbonization equipment.

Technical Parameter of Carbonization Equipment

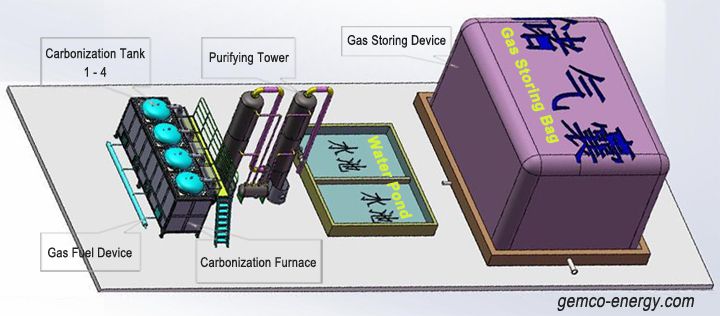

- Carbonization tank is divided into three types, including 4 cans, double cans, single cans.

- Carbonization time: low-temperature: 10h/batch; middle-temperature: 12 h/batch; high-temperature: 14h/batch. The production capacity of every tank is about 250kg.

- Gas production rate: it is related to the carbonization speed and temperature. Generally, for the low-temperature charcoal, the output is 300m3/h; for the high-temperature charcoal, the output is over 500 m3/h. the produced flammable gas is stored by the gas bag, and the pressure is not over 2000 mpa.

- Wood tar, wood vinegar and other thermal decomposition: the output is related o the carbonization speed and temperature. Generally, every ton of charcoal produces over 150kg.

Raw Materials and Finished Charcoal Products

In principle, all the biomass materials with lignin and carbon can be carbonized, but with considering the economic cost, the raw materials which are with high carbon content or high economic value after carbonization are the usual choice, such as, the carbon product made from wood, sawdust, coconut shell etc are the smokeless fuel with high caloric value, or are usually made into activated carbon widely used in the industrial and civil field.

(Common Material and Carbon Products)

Advantages of Smokeless Dry Distillation Carbonization Furnace

- Smokeless and environmental protection: the smoke of the carbonization furnace is stored for use, truly realizing smokeless carbonization.

- Energy saving: except of using for carbonization, the extra smoke is also used for raw material drying, home heating and cooking etc.

- Wide production scope of charcoal briquette: it can be used in high, middle, low temperature.

- High rate of finished products yield: 1.1kg raw material is carbonized into 0.5kg charcoal in low temperature; 1.25 kg is 0.5 kg in high and middle temperature.

- The design of the furnace body is elegant and adaptable to the characteristics of the charcoal industry. The carbonization speed is fast, the floor space is small, the operation is stable, safe and reliable, and the production can be continued.

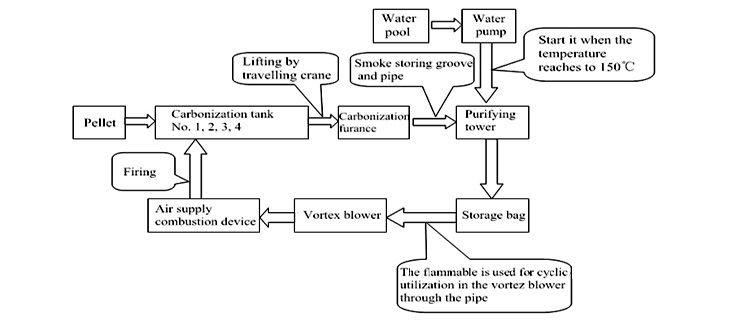

Carbonization Process

(Process Flow Diagram fo Carbonization Equipment)

1. Firstly row the produced charcoal briquettes into the carbonization tank vertically, and seal it tightly ensuring there is no air leakage.

2. Put the carbonization tanks with briquettes into the carbonization furnace one by one, and screw on the thermometer head.

3. Then start the vortex blower to fire one by one (firing for the first time or when there is no gas, the firewood is needed to heat until the gas is discharged out)

4. When the temperature is higher than 150℃, open the exhaust valve behind the purifying tower, then start the water pump for purifying.

5. When the temperature is higher than 200℃, the gas starts to produce.

6. When the temperature reaches to the carbonization requirement, stop the fire for 2 hours; when the carbonization tank is about to come out of the furnace, close the exhaust valve and stop the water pump, then start the next process of lifting and production again.

7. When the temperature of carbonization tank which is about to come out form furnace decreases under 100℃, open the sealing cover, clear the carbonized matters in the smoke vent of sealing cover, to ensure the normal operation of next round.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!